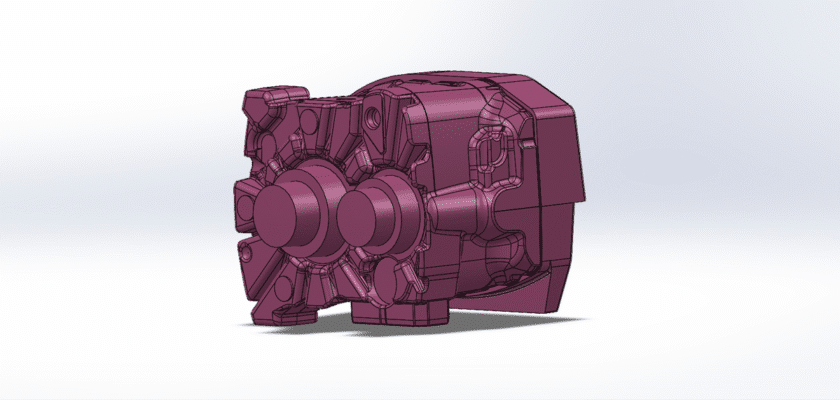

Delve into the core of manufacturing processes with our free technical drawing of Casting Equipment. This drawing is an essential resource for mechanical engineers, foundry technicians, and students. The document provides a comprehensive overview of a typical casting machine’s components, including the mold cavity, pouring basin, gating system, and riser. By downloading these detailed plans, you will gain a profound understanding of how molten material is shaped into finished products, which is a fundamental principle in metallurgy and manufacturing.

Casting is a versatile process used to produce parts from metals and alloys in various shapes and sizes. Our drawing set highlights the intricate design required to achieve a flawless cast, focusing on the flow of molten material and the management of solidification to prevent defects like porosity or shrinkage. These technical diagrams are invaluable for educational purposes, helping you visualize the mechanics of a process that is thousands of years old but still at the heart of modern industry. Whether you are studying foundry operations, designing a new component, or simply curious about how things are made, this drawing is an indispensable addition to your technical library.

Caractéristiques principales :

- Mold and Gating System: The drawing details the design of the mold cavity and the network of channels (gating system) that guides the molten metal from the pouring basin into the mold.

- Riser and Venting: The plans illustrate the riser’s role in supplying molten metal to compensate for shrinkage during solidification and the venting system for releasing trapped gases.

- Pouring Mechanism: The document showcases the mechanism used to pour the molten material into the mold, ensuring a controlled and safe operation.

- Ejection System: The design highlights the system for cleanly removing the cooled, solid part from the mold, a critical step for high-volume production.