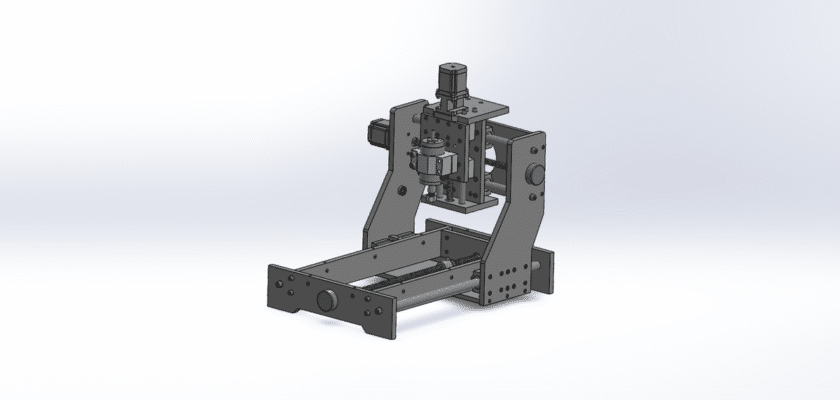

Step into the world of automated craftsmanship with our free Assembly Engraving Machine drawing. This sophisticated machine is engineered to precisely engrave and mark components as they move along an assembly line, ensuring each product has a unique identifier, logo, or critical information. This detailed blueprint is an invaluable resource for engineers, manufacturers, and students who want to understand the intricate mechanics of integrating precision engraving into a high-speed production environment. By automating the marking process, it eliminates the need for manual labor, reduces errors, and ensures consistent quality.

Our comprehensive drawing provides a clear look at the machine’s core components: a robust frame, an automated part feeding system, a high-speed engraving head, and a precise motion control system. You’ll gain a deep understanding of how these elements work in perfect synchronization, allowing for on-the-fly engraving with pinpoint accuracy. Whether you are a professional tasked with designing a new automation solution, a student studying mechatronics, or a hobbyist building a prototype, this drawing offers the foundational knowledge you need. Download it for free and take the first step toward more intelligent and efficient manufacturing.

Caractéristiques principales

- Integrated Assembly Line Design: The blueprint highlights a machine designed to seamlessly integrate into an existing or new assembly line, ensuring a continuous flow of components.

- Automated Part Feeding: Learn how an automated feeding mechanism presents each component to the engraving head with precise timing and positioning.

- High-Speed Engraving Head: The drawing details the use of a powerful engraving tool, such as a laser or diamond stylus, that can create permanent markings quickly and with high resolution.

- Synchronized Motion Control: The design is optimized for motion control, allowing the engraving process to be perfectly synchronized with the movement of the assembly line for on-the-fly marking.

- Versatile Applications: The machine is adaptable to a wide range of materials, including metal, plastic, and ceramics, making it suitable for various industries like electronics, automotive, and medical devices.