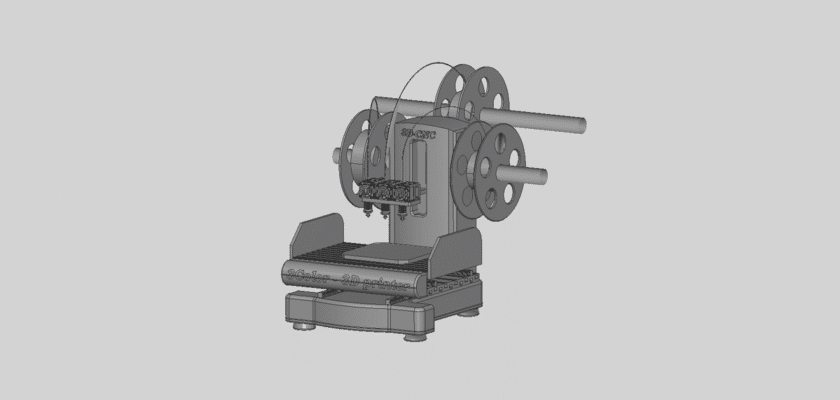

UN three-color 3D printer is an advanced additive manufacturing machine that uses multiple extruders or a special mixing hotend to print objects in up to three different colors or materials simultaneously. This technology allows for the creation of visually complex and highly functional parts without the need for post-processing or manual assembly. It is a game-changer for product designers, artists, and engineers, enabling them to produce prototypes, models, and end-use parts with integrated colors, enhancing both aesthetic appeal and functionality. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade three-color 3D printer. It is an invaluable resource for mechanical engineers, hobbyists, and students who want to understand the intricate mechanical and electronic systems that enable multicolor printing. The plans illustrate the complex filament feeding system, the multi-color extruder head, and the synchronized motion control, giving you the knowledge to build your own machine or simply gain a deeper understanding of this cutting-edge technology.

Caractéristiques principales :

- Multi-Extruder System: The drawing details a system with three separate extruders or a single mixing hotend that allows for the seamless printing of up to three different colors or material types in a single print.

- Synchronized Motion Control: The blueprints showcase a synchronized control system that ensures the correct extruder is activated and the filament is fed with precision, crucial for accurate color changes and high-quality prints.

- Integrated Filament Management: The design includes a sophisticated filament handling system to manage three separate spools, preventing tangles and ensuring a smooth, continuous flow of material to the hotend.

- Robust Frame and Gantry: The machine is engineered with a sturdy frame to minimize vibrations and ensure stability during the printing process, which is essential for producing high-resolution, multi-color objects.