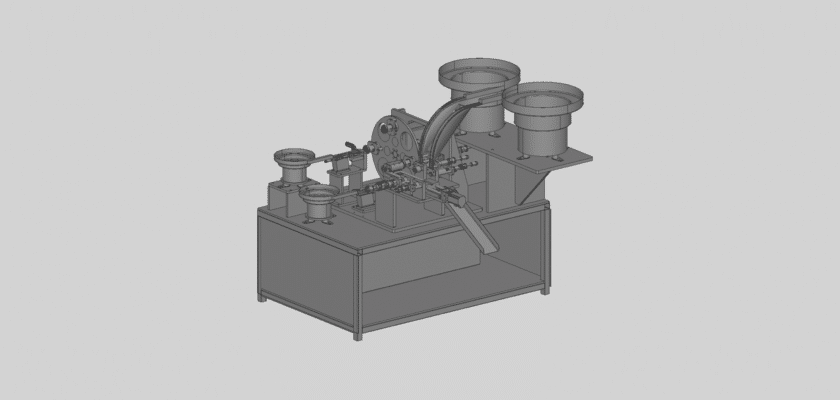

Accelerate your production line development with our professional drawing of Équipement d'assemblage d'onduleurs de moteurs à courant continu. As inverters become critical components in electric vehicles, robotics, and industrial drives, the need for efficient and precise manufacturing solutions is paramount. This free drawing provides a detailed blueprint for an automated or semi-automated workstation designed specifically for inverter assembly.

This is an essential resource for automation engineers, process designers, and machine builders tasked with creating robust manufacturing systems. The design focuses on a logical workflow, component security, and the mechanical systems required for key assembly steps like press-fitting and fastening. Download this invaluable drawing for free to get a head start on your next automation project and to study the principles of modern electronics assembly equipment.

Caractéristiques principales :

- Ergonomic Machine Frame: The drawing details a robust and operator-friendly machine frame, providing a stable foundation for all automated processes and ensuring easy access for maintenance.

- Precision Component Fixtures: Features custom-designed jigs and fixtures that securely hold the inverter’s PCB, heatsink, and housing, guaranteeing perfect alignment for all assembly tasks.

- Automated Press-Fit Station: Showcases a pneumatic or servo-driven press unit engineered for the precise press-fitting of bearings, seals, or thermal components with consistent force.

- Pneumatic System Layout: Provides a clear overview of the pneumatic circuit, including the placement of actuators, grippers, and control valves that drive the machine’s mechanical movements.