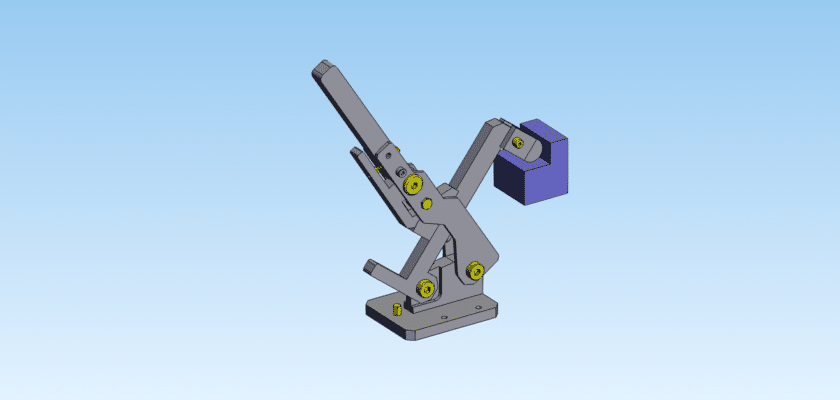

In controlled environments, traditional mechanical clamps are a major source of contamination due to the friction-generated metallic dust and lubricant aerosolization. Our Low-Dust Cam Clamp drawing provides a specialized engineering solution designed to minimize particle emission while maintaining high clamping forces. This technical CAD resource details a unique “friction-reduced” cam profile and sealed pivot points, ensuring that your workholding operations remain within ISO Class 5 or higher cleanroom standards.

The design featured in this package focuses on the elimination of metal-on-metal sliding contact. The drawing includes detailed views of dry-lubricated ceramic bushings, PEEK-coated cam surfaces, and encapsulated spring mechanisms. By downloading this file from MechStream, you gain access to a design that traps wear debris internally or utilizes materials that do not shed particles during the clamping cycle. This is a vital asset for designers of wafer handling systems, surgical instrument fixtures, and pharmaceutical packaging machinery.

Our technical documentation prioritizes material science and surface integrity. The assembly is designed for easy “wipe-down” sterilization, featuring smooth, radiused edges and an absence of blind holes where contaminants could accumulate. Whether you are building a precision alignment fixture for optics or a vacuum-compatible material holder, this drawing provides the exact material specifications, surface roughness ($Ra$) requirements, and “shed-free” coating recommendations needed for a professional-grade cleanroom installation.

Caractéristiques principales :

- Zero-Lube Operation: Specifically engineered for dry-running environments using self-lubricating polymers to prevent outgassing and aerosolized oils.

- Encapsulated Wear Surfaces: Features specialized seals around the cam pivot to contain any internal mechanical wear debris.

- Non-Marring Contact Pad: Detailed designs for ultra-high-molecular-weight (UHMW) or silicone clamp faces that protect the workpiece without shedding.

- Streamlined Exterior Profile: Optimized for laminar airflow environments to prevent turbulence and the accumulation of stagnant dust.

- Corrosion-Resistant Stainless Construction: Utilizes 316L stainless steel or anodized aluminum for compatibility with aggressive cleaning agents (IPA, Bleach).