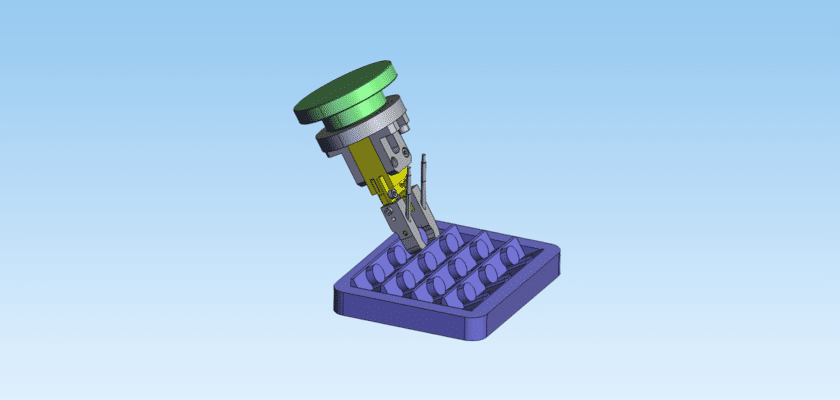

Upgrade your automated production cell with our professional Clamping Mechanism With Workpiece Detection Sensor drawing. In modern manufacturing, a “dumb” clamp can be a liability; if a workpiece is missing or misaligned, the machine may still cycle, leading to damaged tools or wasted energy. This technical blueprint provides a sophisticated solution that combines high-force mechanical clamping with integrated electronic feedback. By incorporating a detection sensor directly into the clamp’s architecture, you ensure the system only proceeds when the part is correctly seated and secured.

The design focuses on the seamless integration of sensing hardware into a rugged mechanical frame. By downloading this drawing from MechStream, you receive a complete assembly guide that includes the mounting bracket for proximity or limit sensors, the adjustable jaw geometry, and the protected cable routing paths. The mechanism is engineered to withstand high clamping pressures while shielding the sensitive electronics from metal chips, coolant, and vibration. This is an essential resource for engineers building robotic assembly stations, CNC fixtures, or safety-interlocked production lines.

Implementing this sensor-integrated mechanism allows for real-time monitoring of the “Clamp Open” and “Clamp Closed” states, as well as “Part Present” verification. The documentation highlights the precise air-gap tolerances required for reliable sensor triggering and provides a variety of jaw face options to suit different workpiece materials. Whether you are aiming for a fully lights-out manufacturing process or simply looking to reduce operator error, this drawing provides the structural integrity and intelligence required for high-stakes industrial applications.

Caractéristiques principales :

- Integrated Sensor Mount: Features a specialized, vibration-isolated bracket designed to house standard M8 or M12 inductive proximity sensors.

- Positive Feedback Logic: Engineered to provide a clear electrical signal only when the workpiece is fully seated and the clamp is locked.

- Heavy-Duty Toggle Linkage: A high-leverage mechanical design that provides maximum holding force with minimal pneumatic or manual input.

- Shielded Cable Management: Includes internal channels to route sensor cables safely away from moving parts and potential pinch points.

- Adjustable Contact Pressure: Features a fine-thread spindle assembly to calibrate the clamping force based on the sensitivity of the workpiece.