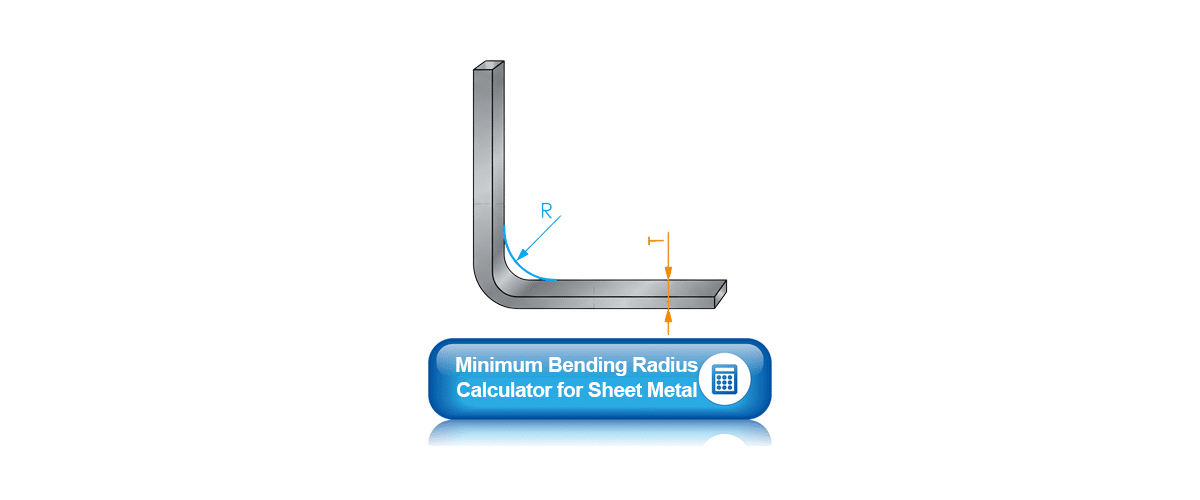

Le Minimum Bending Radius Calculator for Sheet Metal is an essential engineering tool designed to help manufacturers, fabricators, and design engineers accurately determine the smallest allowable bending radius for different sheet metal materials and thicknesses. Using a reliable Minimum Bending Radius Calculator for Sheet Metal helps prevent cracking, excessive thinning, and structural failure during the bending process.

This calculator considers key factors such as material type, tensile strength, thickness, and forming method to ensure safe and efficient bending operations. It is especially useful in press brake applications, custom metal fabrication, and precision manufacturing environments where maintaining dimensional accuracy and surface quality is critical.

By calculating the correct minimum bending radius in advance, manufacturers can reduce trial-and-error adjustments, improve production efficiency, extend tooling life, and ensure consistent bending quality. Whether working with stainless steel, aluminum, or carbon steel, this calculator supports optimized sheet metal design and cost-effective manufacturing processes.

Calculatrice

k-factor: 1.0 × T

Standard bends are typically 90°. Tighter angles may require larger radius.

Minimum Bend Radius (Rmin)

k-Factor Used

1.0

Formula

R = k × T