Table of Contents

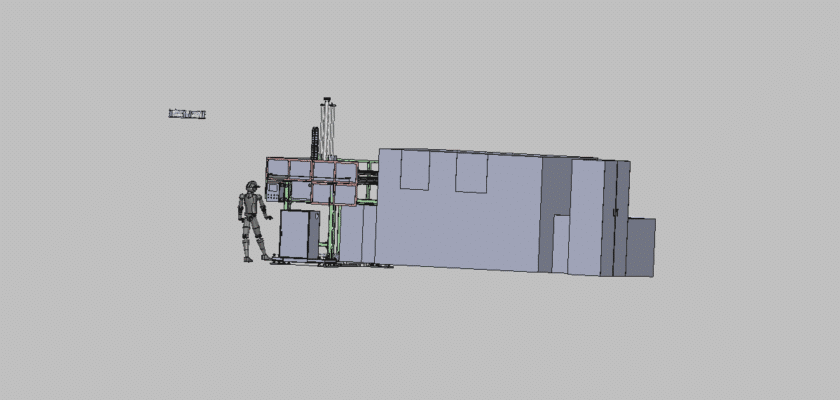

The Large Truss Manipulator Discharging Rack and Grabbing Manipulator Equipment is a sophisticated automated system designed for efficient loading, unloading, and placement of heavy materials in industrial settings. This robust system combines advanced manipulation capabilities with a durable truss structure, making it ideal for manufacturing, logistics, and warehousing applications.

Caractéristiques principales

- Integrated Discharging Rack: The system includes a specialized discharging rack designed to facilitate the quick and efficient unloading of materials, reducing downtime and increasing throughput.

- Grabbing Manipulator: Equipped with an advanced grabbing mechanism that can securely hold and manipulate heavy items, ensuring safe and precise handling.

- Truss Design: Features a lightweight yet strong truss framework that provides stability and minimizes flex under load, enhancing the overall performance of the system.

Components

- Base Frame: A solid foundation that supports the entire manipulator, ensuring stability and consistent performance during operation.

- Truss Assembly: Constructed from high-strength materials, the truss structure offers durability while maintaining a lightweight profile for improved efficiency.

- Grabbing Mechanism: Designed with adaptable fingers or clamps that can accommodate various shapes and sizes of materials, enabling versatile handling.

- Control System: Incorporates an intuitive control interface with sensors and feedback mechanisms for real-time monitoring, allowing for precise control of movements and operations.

Performance Specifications

- Load Capacity: Engineered to handle heavy loads, making it suitable for a wide range of industrial applications where material handling is critical.

- Speed and Efficiency: Designed for rapid operation, minimizing the time required for loading and unloading tasks while maintaining accuracy.

- Durability: Built to withstand harsh industrial environments, featuring components that resist wear and tear for long-term reliability.

Applications

- Manufacturing: Ideal for moving heavy parts and components during assembly processes, enhancing productivity on the shop floor.

- Logistics and Warehousing: Efficiently manages the loading and unloading of goods, streamlining operations in distribution centers and warehouses.

- Construction: Used for handling materials on construction sites, where precision and strength are essential.

Safety and Maintenance

- Caractéristiques de sécurité: Equipped with emergency stop functions and safety sensors to prevent accidents during operation, ensuring a safe working environment.

- Accessibilité de la maintenance: Designed for easy access to components for routine inspections and maintenance, ensuring the system remains operational and effective.

Conclusion

The Large Truss Manipulator Discharging Rack and Grabbing Manipulator Equipment is a cutting-edge solution for modern industrial challenges. Its robust design, advanced manipulation capabilities, and efficiency make it an invaluable asset for enhancing productivity and safety in various operational settings.