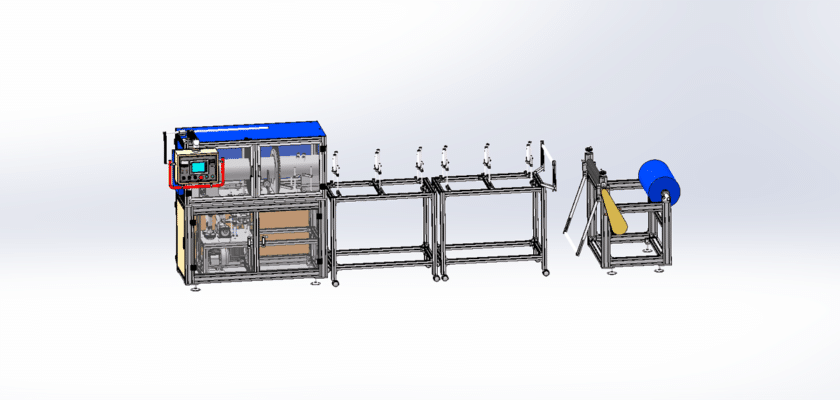

This detailed drawing of the Non-Standard Customized Cylinder Machine illustrates a specialized system designed for the precise manufacturing and assembly of custom cylinder components. Ideal for industries such as automotive, aerospace, and machinery, this machine enhances production flexibility while ensuring high-quality output.

Key Features of the Drawing:

- Customizable Design: Engineered to meet specific production requirements, the machine can be tailored for various cylinder sizes, shapes, and configurations, making it versatile for unique applications.

- Advanced Automation Technology: The system utilizes state-of-the-art automation to streamline the manufacturing process, significantly improving efficiency and reducing manual labor.

- Multi-Function Capabilities: Equipped to perform multiple operations, such as machining, drilling, and assembly, the machine optimizes workflow and minimizes the need for additional equipment.

- Precision Component Handling: High-accuracy alignment tools and fixtures ensure precise positioning during machining and assembly, reducing the likelihood of defects and enhancing product quality.

- User-Friendly Control Interface: An intuitive control panel allows operators to easily set and monitor parameters, facilitating quick adjustments for different cylinder specifications.

- Robust and Durable Construction: Built from high-quality materials, the machine is designed for longevity and reliability, ensuring consistent performance in demanding production environments.

- Integrated Quality Control Systems: Continuous monitoring mechanisms are incorporated to check quality throughout the manufacturing process, ensuring compliance with stringent industry standards.

- Flexible Application Compatibility: Capable of accommodating a wide range of materials, the machine is adaptable for diverse cylinder manufacturing needs in various sectors.

This drawing serves as a vital reference for engineers and manufacturers looking to implement effective and efficient solutions for customized cylinder production in their facilities.