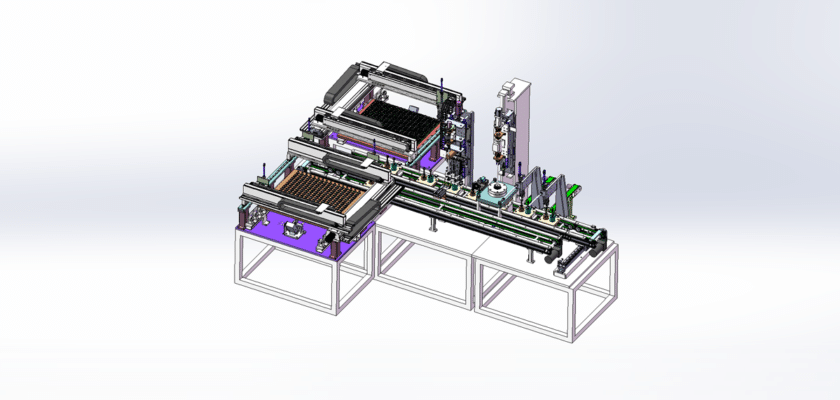

Le Automobile Auxiliary Brake System Automatic Assembly and Testing Line is a state-of-the-art solution for assembling and testing auxiliary brake systems in vehicles. This fully automated system enhances production efficiency, ensuring each brake system is assembled and tested to the highest standards of safety and performance. With its precision and automation, it’s the ideal choice for modern automotive manufacturing lines.

Main Features:

- High-Precision Assembly: The system is designed to assemble auxiliary brake systems with exceptional accuracy, ensuring optimal performance and compliance with automotive safety standards.

- Fully Automated Process: Automation significantly reduces human error and labor costs, increasing throughput while maintaining consistent quality. The system operates seamlessly from assembly to testing, minimizing downtime.

- Integrated Testing Capabilities: Built-in testing stations ensure each brake system is thoroughly tested under controlled conditions to verify its functionality, safety, and performance.

- Flexible and Scalable: Suitable for both small and large-scale production environments, the system can be easily adapted to different models of auxiliary brake systems, making it highly versatile for various automobile manufacturers.

- Durable and Reliable: Constructed with high-quality materials and cutting-edge technology, this assembly and testing line is built to withstand the rigors of continuous production, ensuring longevity and minimal maintenance.

Télécharger le drawing of the Automobile Auxiliary Brake System Automatic Assembly and Testing Line to explore detailed specifications and components of the system. Perfect for engineers, manufacturers, and production planners.