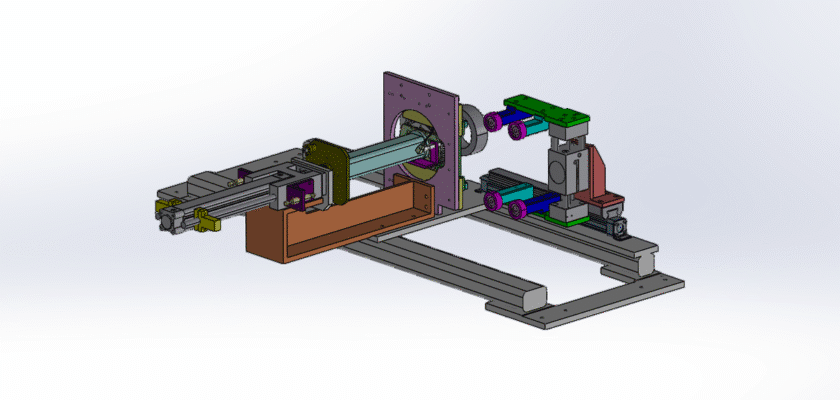

Enhance your assembly line’s precision and speed with our detailed drawing for an Automatic Bearing Installation Workstation. This free downloadable CAD file provides a complete blueprint for building a sophisticated system that automates the critical process of pressing bearings into housings. This resource is essential for manufacturing engineers and automation specialists in industries like automotive, aerospace, and industrial machinery, where flawless bearing installation is paramount.

By downloading this technical drawing, you gain the foundation to construct a workstation that eliminates manual errors, prevents component damage, and ensures consistent quality. The design focuses on robust mechanics and precise control, providing a reliable solution for high-volume production environments. Move beyond manual pressing and implement a state-of-the-art automated process that will elevate your product quality and manufacturing efficiency. This comprehensive plan is your first step toward a more reliable and productive assembly process.

Caractéristiques principales :

- Precision Press Mechanism: The design details a servo-electric or pneumatic press that allows for precise control over insertion force, speed, and final seating depth, preventing bearing damage.

- Alimentation automatisée des composants : Includes provisions for integrating vibratory bowl feeders or tray systems to automatically supply both bearings and housings to the workstation.

- Self-Centering Fixture: Showcases a custom-designed nest or fixture that securely holds the housing and ensures perfect concentric alignment with the bearing before the press cycle begins.

- Contrôle de qualité intégré : Features mounting points for load cells and linear sensors to provide real-time force and position monitoring, allowing for 100% quality verification of each press-fit operation.

- Operator Safety System: The drawing incorporates a complete safety enclosure with light curtains and interlocking access doors to ensure the operator is protected during the machine’s cycle.