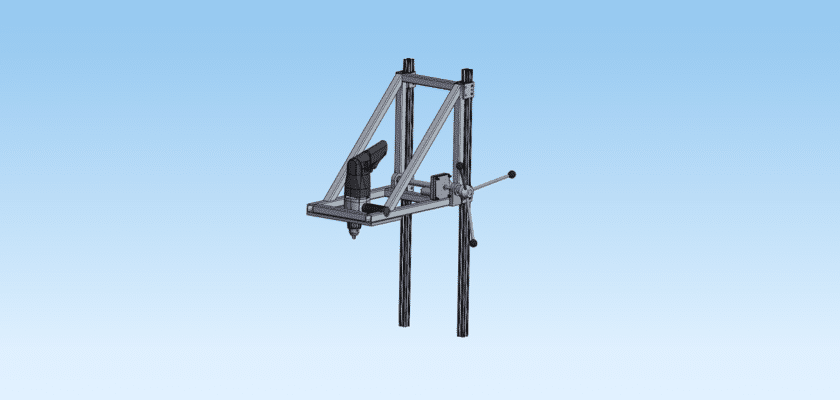

Streamline your production floor with our high-performance Automatic Drilling And Milling Machine technical drawing. This comprehensive blueprint is designed for high-efficiency environments where speed, repeatability, and versatility are paramount. Combining the robust capabilities of a heavy-duty drill press with the precision of a vertical milling center, this automated system is engineered to handle diverse tasks—from deep-hole drilling to complex surface face milling—without the need for constant manual intervention.1

By downloading this professional drawing, you will gain access to a detailed mechanical architecture featuring an automated spindle feed system and programmable logic controller (PLC) integration points. The design focuses on high structural stability to withstand the varying axial and radial forces encountered during simultaneous drilling and milling cycles. The documentation includes precise layouts for the automatic tool feed mechanism, the heavy-duty worktable, and the integrated cooling system essential for maintaining tool longevity. Whether you are upgrading a manual workshop or designing a dedicated high-volume production line for automotive or industrial parts, this drawing provides the industrial-grade tolerances and assembly specifications required to build a reliable and multifunctional machine center.

Caractéristiques principales :

- Automated Cycle Control: Detailed schematics for integrating automatic feed rates and spindle depth stops for high-volume, hands-free production.

- Dual-Function Spindle Head: Engineered with a high-torque motor and precision bearings to handle both high-thrust drilling and lateral milling loads.

- Programmable Worktable Positioning: Features precise X and Y axis travel documentation for accurate workpiece indexing and automated pathing.

- Reinforced Column Design: A high-rigidity frame layout designed to minimize deflection and vibration during heavy material removal.

- Integrated Safety Interlocks: Built-in provisions for emergency stops and protective shielding to ensure a safe automated operating environment.