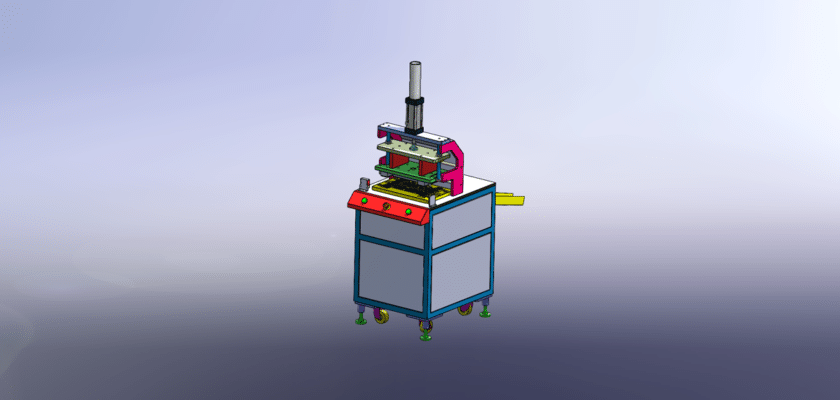

Le Automatic Plastic Water Outlet Cutting Machine is an innovative solution for the precise cutting of plastic water outlets in high-volume manufacturing environments. Designed to offer efficacité, accuracy, et versatilité, this machine is perfect for industries that require consistent, high-quality cuts for plastic components used in plumbing, irrigation, and other water management applications.

Équipé de automatic feeding and cutting mechanisms, this machine reduces the need for manual intervention, thus improving productivity and minimizing human error. It is capable of processing various plastic materials, such as PVC, PE, and others commonly used in water outlet production, making it a highly adaptable solution for different applications.

L’une des caractéristiques clés de cette machine est sa precision cutting system, which ensures clean, uniform cuts with minimal material waste. The Système de contrôle CNC allows for precise adjustments to cutting dimensions, ensuring that the water outlet components meet the required specifications every time. The fonctionnement à grande vitesse also boosts throughput, making it ideal for large-scale production.

Le interface conviviale simplifies machine setup and operation, while the advanced safety features—such as overload protection and emergency stop buttons—ensure a safe working environment for operators. Additionally, the automatic unloading system further enhances efficiency by seamlessly removing the cut pieces and preparing the machine for the next cycle.

Dans l’ensemble, le Automatic Plastic Water Outlet Cutting Machine is a reliable and efficient solution for businesses looking to automate their plastic water outlet production, providing high precision, reduced operational costs, and increased productivity.