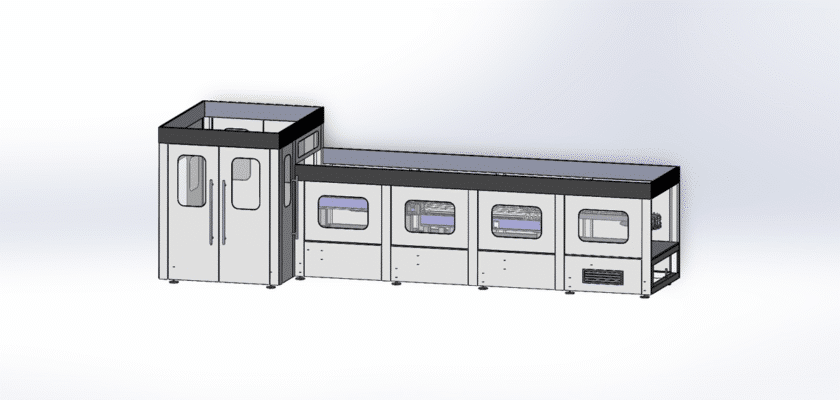

Are you involved in the plastic packaging industry or manufacturing equipment for beverage and bottling lines? MechStream offers the essential free technical dessin pour un standard Bottle Blowing Machine Frame! This complex industrial machine is the heart of PET plastic bottle production, utilizing heat and high-pressure air to stretch and mold preforms into finished containers. This detailed machine frame design is invaluable for automation engineers, packaging manufacturers, and industrial machinery fabricators seeking robust and high-speed production solutions.

This free blueprint is an essential asset for designers focused on high-speed operation, stability, and integration of hydraulic and pneumatic systems. The detailed dessin provides precise dimensional data, critical specifications for the main machine frame (designed to handle high forces), mounting points for the clamping unit and oven/heating system, and routing channels for high-pressure air lines. Utilizing this powerful drawing ensures your bottle blowing machine fabrication is structurally sound, minimizes vibration during rapid cycling, and guarantees reliable performance in continuous production environments. Stop designing complex machinery from scratch. Télécharger the professional-grade Bottle Blowing Machine Frame Drawing today and secure the robust foundation for your packaging production line!

Caractéristiques principales :

- High-Strength Frame Design: Specifies robust structural steel members and bracing required to withstand the immense clamping forces and high vibration associated with stretch blow molding.

- Component Mounting Points: Includes precise mounting locations for the heating oven/preform feeder, the main clamping/molding station, and the high-pressure air distribution block.

- Vibration Dampening Details: Features design elements or material recommendations for machine feet and base plate anchoring to minimize operational vibration and ensure product consistency.

- Service Access and Safety: Details secure access panels and covers necessary for maintenance of internal pneumatic and mechanical components, adhering to industrial safety standards.

- Pneumatic System Integration: Provides specified routing channels and connection points for the high-pressure air lines crucial for the stretching and blowing process.