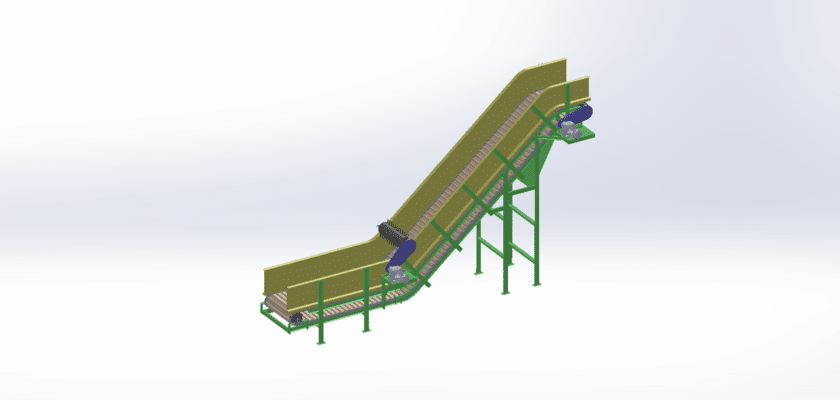

Le Convoyeur à chaîne is a robust material handling system designed to transport heavy or bulk materials efficiently across various industrial applications. Utilizing a chain mechanism, this conveyor is ideal for environments that require the movement of large items or significant weight, ensuring reliability and durability during operation.

Caractéristiques principales :

- Mécanisme à chaîne: The conveyor operates using a series of interconnected chain links or slats that provide high strength and stability. This mechanism is specifically designed to support heavy loads, making it suitable for industries such as manufacturing, automotive, and mining.

- Structure du cadre: Constructed from high-strength steel or aluminum, the frame offers stability and durability. The design is engineered to withstand the stresses of continuous operation and heavy material transport.

- Ensemble d'entraînement: The drive mechanism includes a motor, sprockets, and gear systems that provide the necessary power to move the chain. This assembly ensures consistent speed and reliable operation, critical for efficient material handling.

- Système de tension: An adjustable tensioning mechanism is integrated to maintain optimal tension on the chain, preventing slippage and ensuring smooth operation. Proper tension is essential for the longevity of the conveyor system.

- Rouleaux de support et guides: The conveyor includes support rollers and guides that help keep the chain aligned and reduce friction during operation, further enhancing efficiency and minimizing wear on components.

- Caractéristiques de sécurité: Designed with safety in mind, the conveyor incorporates emergency stop buttons, safety guards, and accessible maintenance points, ensuring a safe working environment for operators.

- Conception modulaire: The chain conveyor often features a modular design, allowing for easy customization and integration into existing production lines, making it adaptable to specific operational needs.