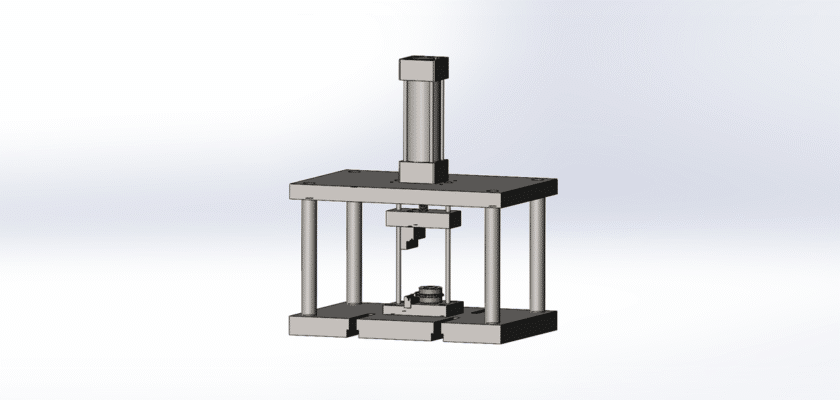

Maîtrisez l'art de la fabrication de bobines avec notre Outil de pliage de bobines dessin, disponible pour téléchargement gratuit sur MechStream ! Ce dessin technique détaillé est une ressource essentielle pour les ingénieurs, techniciens et amateurs impliqués dans la production de transformateurs, d'inducteurs et d'autres composants bobinés. Il offre un aperçu complet de la conception et du fonctionnement d'un outil spécialisé utilisé pour former et cintrer avec précision les bobines, garantissant un ajustement et un alignement parfaits pour le bobinage. Le document décrit les dimensions et caractéristiques critiques de l'outil, notamment les mandrins de cintrage, les mécanismes de serrage et la plaque de base, tous conçus pour obtenir des résultats constants et reproductibles. En téléchargeant ce dessin, vous approfondirez votre compréhension des principes du pliage de tôle appliqués aux composants électriques délicats. Cet outil est essentiel pour le prototypage à petite échelle comme pour la fabrication en grandes séries, car il garantit l'intégrité et la précision dimensionnelle de la bobine, ce qui a un impact direct sur les performances de la bobine finale. C'est l'occasion d'accéder à des informations de conception de qualité professionnelle qui amélioreront considérablement vos projets et vos capacités de production.

Caractéristiques principales :

- Mécanisme de pliage précis : Le dessin détaille les mandrins et les formes de cintrage de l'outil, conçus pour réaliser des cintrages précis et nets dans le matériau de la bobine. Cette précision est essentielle pour garantir le bon ajustement de la bobine dans la bobine et éviter d'endommager l'isolant du fil lors du bobinage.

- Conception réglable : Les plans présentent une configuration ajustable permettant d'adapter l'outil à différentes tailles et formes de bobines. Cette polyvalence en fait un atout précieux pour les ateliers réalisant divers projets de bobinage, réduisant ainsi le besoin de multiples outils spécialisés.

- Construction durable : Le plan précise l'utilisation de matériaux robustes, tels que l'acier à outils ou l'aluminium haute résistance, pour les composants de l'outil. Cela garantit que l'outil de pliage résistera à une utilisation répétée et conservera sa précision au fil du temps, ce qui en fait un élément fiable de votre processus de production.

- Utilisation ergonomique et sûre : La conception intègre des caractéristiques favorisant la simplicité d'utilisation et la sécurité, telles que des guides d'alignement clairement marqués et des points de serrage stables. Ces détails contribuent à minimiser les erreurs de l'opérateur et à réduire les risques de blessures, tout en garantissant une qualité de production optimale.