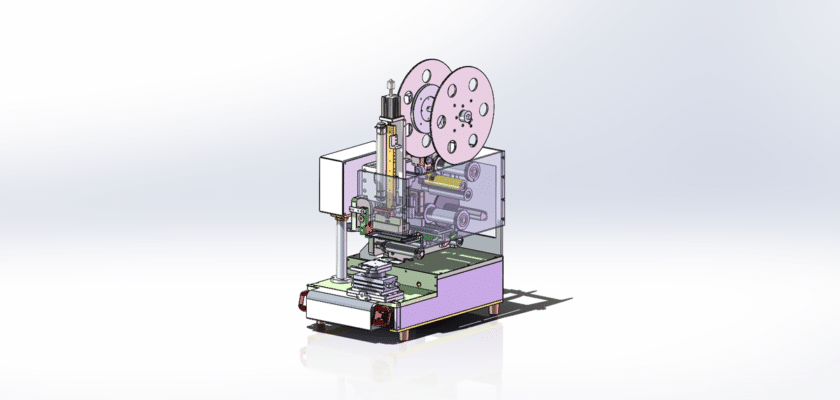

A Complete Labeling Machine Drawing is a comprehensive technical illustration that outlines the design, components, and functionality of a fully automated labeling machine used in various industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods. This drawing serves as a valuable reference for engineers, technicians, and production managers involved in the design, assembly, and maintenance of labeling machinery.

Caractéristiques principales :

- Disposition générale: A detailed view of the machine’s structure, showcasing the arrangement of all components and their interactions during the labeling process.

- Système d'alimentation des produits: Diagrams illustrating the mechanisms that transport products to the labeling area, which may include conveyor belts, rollers, or automated feeders designed for consistent flow.

- Mécanisme d'alimentation des étiquettes: Representation of systems that manage label rolls or sheets, including unwinding systems, tension controls, and alignment guides to ensure accurate label handling.

- Tête d'étiquetage: Details about the applicator mechanism, which may utilize rollers, brushes, or blow-on systems for precise application of labels onto product surfaces.

- Caractéristiques de réglage: Information on adjustable components allowing the machine to accommodate different product sizes and shapes, ensuring versatility in labeling applications.

- Panneau de contrôle: Illustrations of the central control unit that manages the operation of the machine, providing operators with the ability to monitor processes, adjust settings, and access real-time performance data.

- Interface utilisateur: Information about the touchscreen or control panel that offers intuitive access to machine settings, including label dimensions, application speed, and positioning adjustments.

- Systèmes de contrôle de la qualité:Schémas montrant des capteurs ou des caméras intégrés qui surveillent le processus d'étiquetage pour plus de précision, garantissant que chaque étiquette est appliquée correctement et adhère correctement.

- Systèmes de sortie de données:Informations sur la manière dont les données de production, y compris le nombre d'étiquettes et les mesures de qualité, sont enregistrées et communiquées, avec des affichages numériques pour un retour d'information immédiat.

- Cadre mécanique: Détails sur les composants structurels qui soutiennent la machine, assurant la stabilité et la durabilité pendant le fonctionnement.

- Caractéristiques de sécurité: Information regarding safety mechanisms, such as emergency stops, safety guards, and sensors designed to ensure safe operation throughout the labeling process.

- Alimentation électrique: Information about the electrical requirements and backup systems to ensure reliable operation of the machine.

This drawing provides a comprehensive reference for understanding the complete labeling machine’s design, ensuring high standards of efficiency, accuracy, and operational effectiveness in the labeling process across various industries.