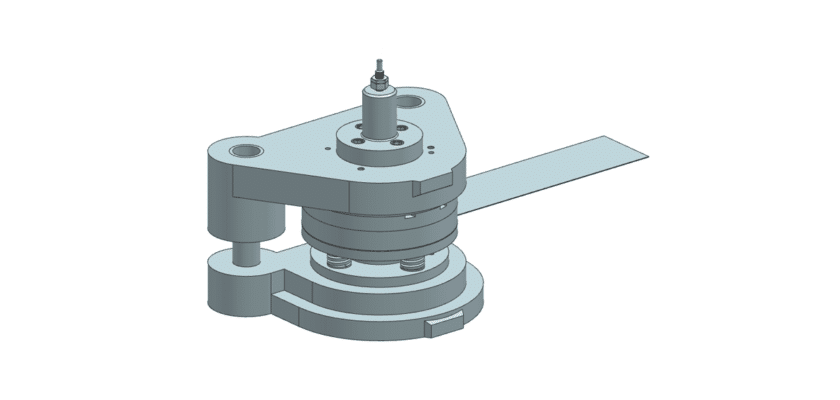

Maximize your stamping accuracy with our professional Compound Die 6 Creo technical documentation. Compound dies are renowned for their efficiency, allowing for the simultaneous execution of blanking and piercing operations in a single station. This specific design package is built for the PTC Creo environment, leveraging its robust parametric capabilities to ensure that every component—from the punch holder to the die shoe—maintains perfect geometric relationships. This ensures that the concentricity between the part’s outer edge and internal features is held to the tightest possible tolerances.

The provided dessin package includes the full assembly structure and detailed 2D production drawings exported for immediate workshop use. By analyzing the complex nesting of the piercing punch within the blanking die through these blueprints, engineers can optimize the shear load and reduce energy consumption per stroke. We offer these high-fidelity CAD resources for free to help designers master the sophisticated clearances and mechanical timing necessary for high-volume industrial production.

Our files are optimized for the Creo workflow, ensuring that you can easily modify dimensions or material specs while maintaining assembly integrity. Whether you are fabricating precision shims or intricate automotive brackets, this compound die design provides a fail-safe blueprint for professional toolmakers. Download this essential resource today to streamline your manufacturing process and reduce the risk of part rejection during quality control.

Caractéristiques principales :

- Synchronized Piercing and Blanking: Engineered to perform multiple operations at once, ensuring 100% concentricity of features.

- Creo Parametric Framework: Fully constrained assembly model that allows for rapid scaling and design adjustments.

- Sophisticated Ejection System: Features detailed layouts for internal knockouts and spring-loaded strippers to prevent part sticking.

- Heavy-Duty Pillar Alignment: High-precision guide post specifications to ensure the die stays aligned over millions of cycles.

- High-Carbon Tool Steel Spec: Designed for use with D2 or similar alloys to handle the intense stresses of high-speed stamping.