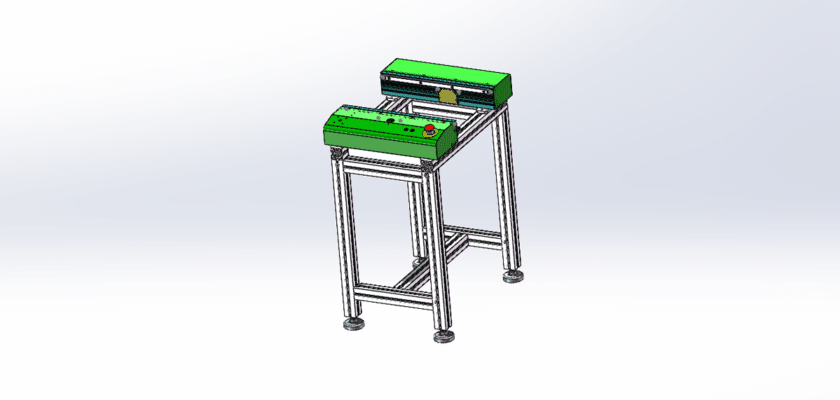

Le dessin de connexion entre les lignes de production SMT illustre l'intégration de plusieurs lignes de production SMT, en mettant l'accent sur un flux de travail efficace et une manutention des matériaux dans un environnement de fabrication électronique.

Caractéristiques principales :

- Convoyeurs interconnectés:Le dessin met en évidence les systèmes de convoyeurs qui relient différentes lignes SMT, facilitant le transfert transparent des composants et des assemblages entre les étapes de production.

- Optimisation des flux:Les annotations indiquent le flux optimal de matériaux, montrant comment la conception minimise les retards et améliore le débit tout au long du processus de production.

- Alignement et positionnement: Détails sur l'alignement précis des équipements SMT pour garantir un placement précis des composants, y compris les tolérances et les exigences spatiales pour un fonctionnement efficace.

- Conception modulaire:Le dessin reflète une approche modulaire, permettant une évolutivité et une adaptabilité faciles des lignes de production pour s'adapter aux besoins changeants de production.

- Intégration des systèmes de contrôle:Informations sur les systèmes de contrôle utilisés pour synchroniser les opérations entre les lignes connectées, garantissant une production coordonnée et minimisant les erreurs.

- Considérations de sécurité:L'inclusion de dispositifs de sécurité tels que des mécanismes d'arrêt d'urgence, des barrières de sécurité et des voies d'accès dégagées pour le personnel afin de garantir un environnement de travail sûr.

- Points d'accès de maintenance:Zones désignées pour un accès facile aux machines et aux systèmes de convoyage pour l'entretien de routine et le dépannage, réduisant les temps d'arrêt et améliorant la fiabilité.

Ce dessin constitue une ressource précieuse pour les ingénieurs, les responsables de production et les équipes d'installation, fournissant des informations détaillées sur la conception et la mise en œuvre de lignes de production SMT interconnectées pour une efficacité et une productivité accrues dans la fabrication électronique.