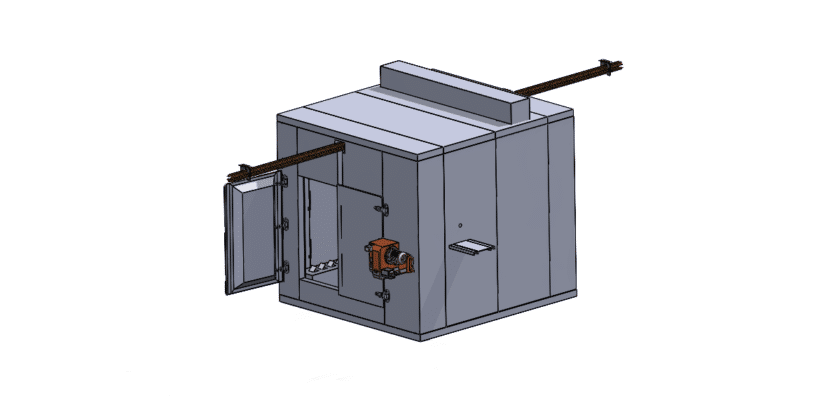

The Conveyor Powder Coating Furnace drawing presents a detailed schematic of a specialized furnace designed for the efficient powder coating of materials in industrial applications.

Caractéristiques principales :

- Furnace Structure: The drawing illustrates the robust construction of the furnace, highlighting materials and insulation used to withstand high temperatures while maintaining energy efficiency.

- Conveyor System: A representation of the integrated conveyor system is provided, showing how items are continuously fed into the furnace for uniform powder coating, ensuring consistent coating thickness.

- Heating Elements: Details on the heating elements, including their arrangement and specifications, are included to demonstrate how they provide even heat distribution throughout the furnace.

- Temperature Control: Information on the temperature control systems, including sensors and control panels, is depicted to ensure precise monitoring and adjustments during the coating process.

- Exhaust and Ventilation: The drawing outlines the exhaust system designed to remove fumes and maintain air quality, along with ventilation features that prevent overheating and ensure safe operation.

- Caractéristiques de sécurité: Important safety components, such as emergency shutoff switches, thermal overload protection, and safety interlocks, are clearly marked to enhance operator safety.

- Maintenance Access: Design considerations for easy access to critical components for routine maintenance and troubleshooting are included, promoting efficient upkeep of the furnace.

- Integration Capabilities: The drawing highlights points for integrating the furnace with other production equipment, such as pre-treatment systems and drying ovens, to create a seamless workflow.

This drawing serves as an essential resource for engineers, production managers, and maintenance teams, providing comprehensive information for the design, installation, and operation of conveyor powder coating furnaces in various industrial settings.