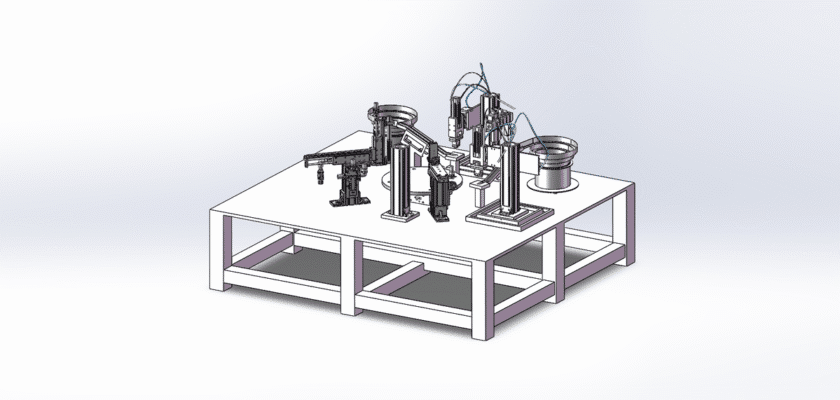

Découvrez le secret des coils parfaits avec notre professionnel Machine d'enroulement de tubes en cuivre dessin, disponible pour téléchargement gratuitCe plan détaillé est un guide essentiel pour les ingénieurs, les fabricants et les bricoleurs qui souhaitent construire ou comprendre les principes d'une machine conçue pour l'enroulement précis de tubes en cuivre. Contrairement aux simples outils de cintrage, cette machine spécialisée est conçue pour créer des bobines hélicoïdales uniformes, essentielles pour des applications telles que les échangeurs de chaleur, les systèmes de réfrigération et les tuyauteries sur mesure. Ce plan détaille en détail les principaux composants de la machine, notamment le système d'entraînement, le mandrin d'enroulement et les mécanismes de tension. En téléchargeant ce plan, vous acquerrez les bases de la conception mécanique nécessaire pour éviter le vrillage, l'aplatissement et le retour élastique des tubes pendant l'enroulement. C'est une ressource précieuse pour les étudiants travaillant sur des projets, les professionnels optimisant leur ligne de production ou toute personne souhaitant explorer le monde fascinant du formage automatisé de tubes.

Caractéristiques principales :

- Mandrin de précision et enroulement : Le dessin met en évidence l'utilisation d'un mandrin rotatif et d'un mécanisme d'alimentation coordonné pour garantir un diamètre et un pas de bobine constants. Cette précision est essentielle au maintien de l'intégrité structurelle et de l'efficacité du transfert thermique du produit final.

- Système de tension contrôlé : Le plan illustre un système de tension intégré conçu pour appliquer une force uniforme au tube de cuivre lors de son enroulement. Cette caractéristique est essentielle pour éviter les plis et garantir un enroulement serré et des dimensions précises de la bobine finale.

- Mécanisme d'entraînement robuste : La conception comprend un moteur puissant et un réducteur fournissant le couple nécessaire à l'enroulement de tubes de différents diamètres et épaisseurs de paroi. Le système d'entraînement est conçu pour un fonctionnement fluide et continu, essentiel à la production de bobines sans soudure de haute qualité.

- Conception réglable et polyvalente : Le dessin détaille comment divers composants, tels que le mandrin et les guides d'alimentation, peuvent être ajustés pour s'adapter aux différents diamètres de tubes et aux spécifications des bobines. Cette adaptabilité permet à la machine de s'adapter à un large éventail d'applications et de projets sur mesure.