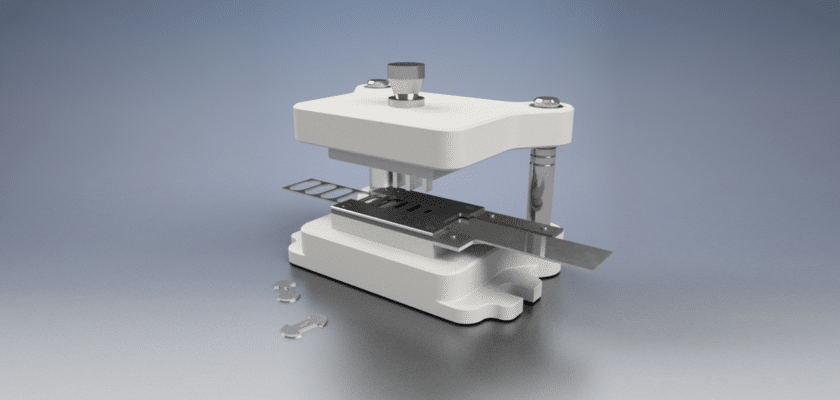

Elevate your industrial design standards with our comprehensive Die 6 Catia technical documentation. This professional-grade die assembly is specifically modeled within the CATIA ecosystem, the industry standard for aerospace and automotive engineering. It is designed to handle complex stamping and forming tasks that require extreme dimensional stability and intricate surface transitions. By utilizing this drawing package, your team can harness the power of parametric modeling to ensure that every punch, die block, and stripper plate maintains its geometric integrity even through multiple design iterations.

The downloadable dessin package provides full 3D assembly structures and detailed 2D drafting sheets, ensuring a clear path from digital concept to the tool room. By examining the hierarchical tree and constraint-driven layout, engineers can gain deep insights into high-end tool architecture, including optimized cooling channels and precision alignment systems. We provide these high-fidelity resources for free to help designers master the advanced surfaces and tight tolerances required for modern metal forming.

Our CATIA-optimized files ensure that you can perform advanced kinematic simulations to verify the stroke and clearance of the “Die 6” assembly before fabrication. This proactive approach significantly reduces the risk of tool interference and ensures a longer life cycle for your press components. Download this essential CAD asset today to streamline your workflow and deliver world-class tooling solutions with confidence.

Caractéristiques principales :

- CATIA Parametric Framework: Fully constrained assembly allowing for rapid scaling and adjustment of complex surface geometries.

- Optimized Surface Finish: Engineered with CATIA’s generative shape design for smooth material flow and minimal friction.

- Precision Guide Bushings: Detailed specifications for high-tolerance alignment pins to ensure sub-micron accuracy during operation.

- Integrated Ejection Logic: Features advanced mechanical layouts for spring-loaded strippers and automated part removal.

- Spécifications matérielles avancées : Designed for implementation with high-performance tool steels like SKD11 or D2 for maximum durability.