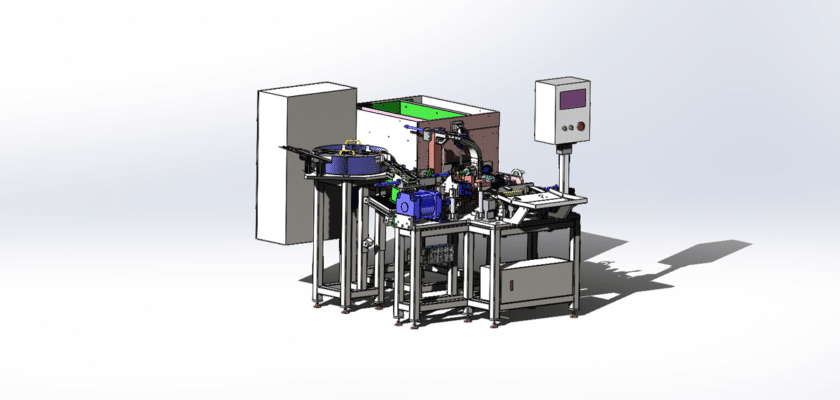

This detailed drawing of the Drum Bottom Valve Press Equipment illustrates a specialized system designed for the precise assembly and pressing of bottom valves used in various drum applications. Ideal for manufacturers in industries such as chemicals, food and beverage, and pharmaceuticals, this equipment enhances production efficiency while ensuring high-quality outputs.

Principales caractéristiques du dessin :

- Processus de pressage automatisé: The equipment utilizes advanced automation technology to streamline the pressing of bottom valves, significantly increasing throughput and reducing manual intervention.

- High Precision Pressing Mechanism: Equipped with precision dies and adjustable pressure settings, the system ensures accurate assembly of valves, meeting stringent quality and performance standards.

- Interface de contrôle conviviale: The intuitive control panel allows operators to easily program and monitor the pressing process, facilitating quick adjustments for different valve sizes and configurations.

- Compatibilité des matériaux polyvalents: Designed to accommodate various materials used for valve construction, including metals and plastics, making it adaptable for diverse applications.

- Fonctionnalités de contrôle qualité intégrées: Features built-in inspection systems to verify that each pressed valve meets quality standards, minimizing defects and enhancing overall reliability.

- Construction robuste et durable:Construit à partir de matériaux de haute qualité, l'équipement est conçu pour la longévité et la fiabilité, garantissant des performances optimales dans des environnements de production exigeants.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient solutions for drum bottom valve assembly in their production lines.