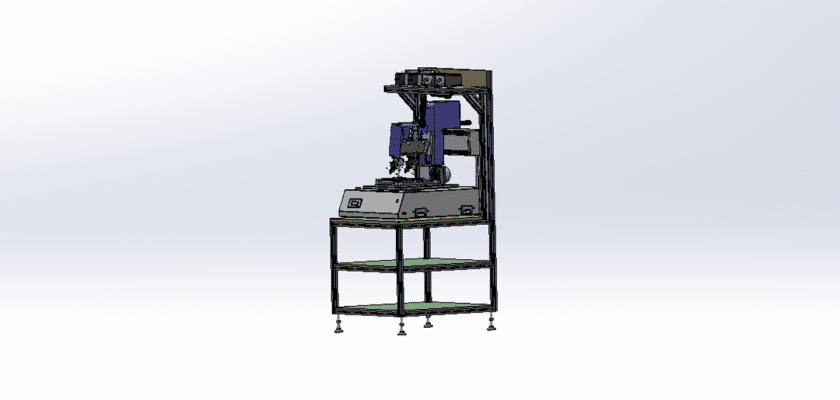

This detailed drawing of the Dual-Head Automatic Soldering Machine illustrates a specialized system designed for high-efficiency soldering of electronic components. Ideal for manufacturers in the electronics industry, this machine enhances productivity while ensuring precise and reliable solder joints.

Key Features of the Drawing:

- Dual-Head Design: The machine features two independent soldering heads that operate simultaneously, allowing for increased throughput and the ability to solder multiple components at once.

- Automated Soldering Process: Equipped with advanced automation technology, the system streamlines the soldering process, significantly reducing manual labor and cycle times while maintaining high precision.

- High Precision Soldering Mechanism: Precision controls ensure accurate temperature and timing during the soldering process, meeting stringent quality standards for solder joints.

- User-Friendly Control Interface: The intuitive control panel allows operators to easily program and monitor soldering parameters, facilitating quick adjustments for different component types and sizes.

- Versatile Component Compatibility: Designed to accommodate a variety of electronic components, including surface-mount (SMD) and through-hole devices, making it adaptable for diverse applications.

- Integrated Quality Control Features: Features built-in inspection systems to verify that each solder joint meets quality standards, minimizing defects and enhancing overall reliability.

- Robust and Durable Construction: Built from high-quality materials, the machine is engineered for longevity and reliability, ensuring optimal performance in high-volume production environments.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient soldering solutions in their assembly lines.