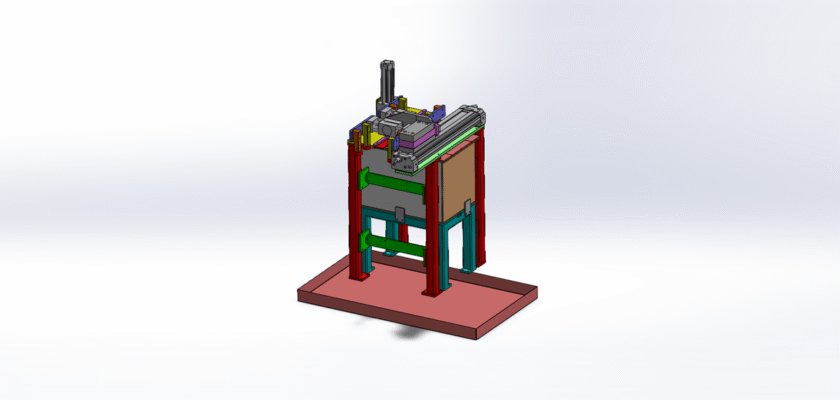

Optimisez votre production avec notre exclusivité Machine d'emballage double en ligne dessin, disponible pour téléchargement gratuitCe document technique de qualité professionnelle offre un aperçu détaillé d'un système d'emballage automatisé à grande vitesse, conçu pour traiter simultanément deux lignes de produits. Cette machine de pointe révolutionne les entreprises qui cherchent à doubler leur productivité et leur efficacité. Ce plan est une ressource précieuse pour les ingénieurs, les responsables de production et les étudiants qui souhaitent comprendre la coordination complexe des convoyeurs, des bras robotisés et des mécanismes de scellage. En étudiant ce plan, vous comprendrez parfaitement comment une seule machine peut gérer deux entrées et sorties, assurant ainsi un fonctionnement synchronisé et continu. Que vous envisagiez d'intégrer une nouvelle machine à votre usine, d'optimiser une machine existante ou que vous souhaitiez simplement approfondir vos connaissances en automatisation industrielle, ce plan est un outil essentiel pour accélérer votre apprentissage et votre processus de conception.

Caractéristiques principales :

- Production à deux voies : Le plan illustre clairement les deux lignes de production parallèles, chacune dotée de ses propres postes d'alimentation, de remplissage et de scellage. Cette conception à deux voies permet une augmentation significative de la cadence de production, car une ligne peut fonctionner pendant que l'autre est en cours de préparation ou de maintenance.

- Système de contrôle synchronisé : Le schéma illustre le système de contrôle centralisé, un élément essentiel qui assure la parfaite synchronisation des deux lignes de production. Cela évite les goulots d'étranglement et assure un flux de produits fluide du début à la fin, optimisant ainsi l'efficacité et minimisant les déchets.

- Capacité d'emballage polyvalente : Les plans mettent en avant une conception flexible, facilement adaptable à différentes tailles de produits et matériaux d'emballage. Cette polyvalence rend la machine adaptée à un large éventail d'industries, notamment l'agroalimentaire, l'industrie pharmaceutique et les biens de consommation.

- Alimentation et scellage automatisés des produits : Les schémas techniques détaillent les mécanismes d'alimentation automatisés qui positionnent précisément les produits à emballer, ainsi que les unités de scellage à grande vitesse qui garantissent un produit final sûr et inviolable. Ces fonctionnalités automatisées réduisent considérablement les coûts de main-d'œuvre et améliorent la régularité de l'emballage.