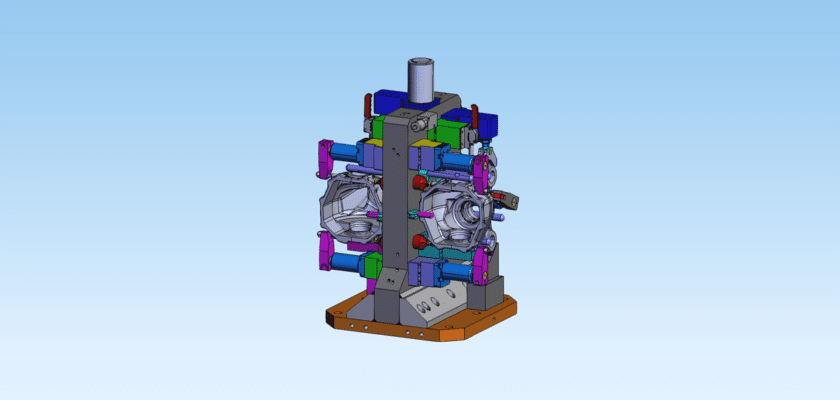

Optimize your production throughput with our professional Dual-Station Hydraulic Fixture For Housings drawing. In high-volume manufacturing environments, minimizing machine downtime is critical; this dual-station design allows for “hidden” loading times, where one station is being machined while the operator loads or unloads the second. This technical drawing provides a comprehensive engineering blueprint for a fixture specifically tailored to the complex geometries of motor housings, gearbox casings, or pump bodies.

The drawing details a sophisticated hydraulic circuit that ensures independent or simultaneous clamping across both stations. By utilizing this resource, engineering teams can implement a rigid work-holding solution that maintains extreme repeatability and parallelism across multiple workpieces. The design focuses on heavy-duty construction to dampen vibrations during aggressive cutting cycles, ensuring that the tight tolerances required for housing bores and mating surfaces are consistently met. Whether you are upgrading a vertical machining center or a horizontal cell, this drawing offers the structural and hydraulic specifications necessary to build a world-class production tool.

Caractéristiques principales :

- Twin-Station Efficiency: Optimized layout for dual-zone machining, significantly increasing spindle utilization and overall output.

- Independent Hydraulic Control: Features detailed plumbing schematics for separate clamping circuits, allowing safe loading while the spindle is active.

- Custom Contour Support: Includes design templates for interchangeable v-blocks and locators specifically shaped for cylindrical or irregular housing profiles.

- High-Rigidity Baseplate: Engineered with a heavy-duty manifold base to eliminate flexing and ensure long-term dimensional stability.

- Automated Interface Ready: The design includes standardized connection points for seamless integration with CNC rotary tables or robotic loading arms.