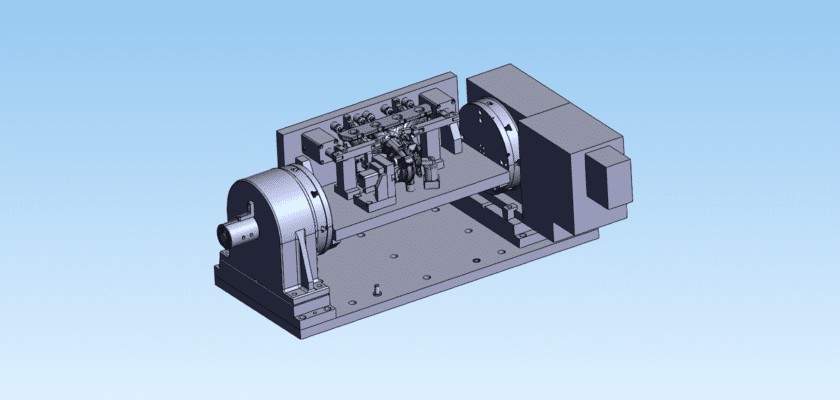

Achieve perfect flange alignment and vibration-free machining with our exclusive, free drawing package pour le Precision Hydraulic Tooling Fixture For Engine Exhaust Manifold! Machining exhaust manifolds is notoriously difficult due to their complex, asymmetrical shapes and the thin-walled cast iron or stainless steel construction. This specialized hydraulic fixture is absolutely critical for automotive manufacturers and Tier-1 suppliers, providing the uniform clamping pressure and rigid support necessary to prevent part distortion during high-speed milling and drilling of the mounting faces.

Ce comprehensive technical drawing set provides the detailed blueprints for constructing a high-performance workholding solution specifically for engine exhaust components. The plans detail the custom-contoured support nests, the strategic placement of hydraulic swing clamps and work supports to counteract cutting forces, and the internal manifold routing for the high-pressure oil lines. Automotive tool designers, CNC engineers, and production managers will find these accurate, industry-standard drawings invaluable for building or optimizing dedicated machining cells. Stop struggling with manual setups that lead to warped flanges and leaky gaskets. By downloading this critical design asset today, you gain the foundational technical knowledge for building a compliant and highly stable manifold fixture. Secure your free engine tooling drawing now and ensure every manifold meets strict OEM tolerances!

Caractéristiques principales :

- Contoured Workpiece Nesting: Detailed blueprints specifying the precision-machined support points designed to match the irregular casting profile of the exhaust manifold.

- Vibration-Dampening Work Supports: Schematics illustrating the hydraulic “smart” supports that advance to touch the part and lock in place, providing rigidity to thin-walled sections without causing deformation.

- Sequence-Controlled Clamping: Drawings detailing the hydraulic circuit that ensures the manifold is seated against the datum pins before the primary swing clamps apply final pressure.

- Thermal Expansion Accommodation: Blueprints showing the fixture design considerations for handling parts that may still be warm from previous processes or undergo thermal shift during heavy milling.

- Chip and Coolant Shedding Design: Details on the sloped surfaces and protective seals designed to prevent the build-up of abrasive cast iron dust and cooling fluids within the hydraulic mechanisms.