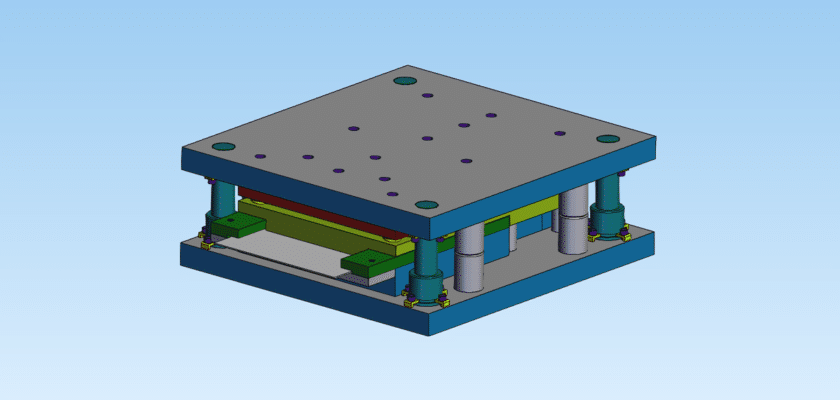

Accelerate your learning curve and optimize your production layouts with our comprehensive technical documentation for the Example Progress Tool. A progressive tool is the height of stamping efficiency, performing a sequence of operations—such as piercing, forming, and blanking—at different stations within a single die set. This example drawing serves as a master blueprint for understanding how a metal strip advances through various stages to produce a finished component with every stroke of the press.

The provided dessin package offers an exhaustive look at the pitch calculation, pilot pin positioning, and strip lifter mechanisms that are vital for high-speed automated production. By analyzing this professional reference, engineers can gain deep insights into how to balance tonnage across the die and how to design effective scrap shedding channels. We provide these high-fidelity CAD resources for free to help designers visualize the complex interactions between moving parts in a multi-stage environment.

Our files are formatted for seamless integration into all major 3D engineering platforms. This allows your team to study the timing of the stripper plates and the precision of the finger stops in a virtual environment before beginning a custom build. Whether you are a student or a veteran toolmaker, this example provides the structural foundation needed to design robust, high-volume tooling solutions. Download this essential resource today to master the flow of progressive metal stamping.

Caractéristiques principales :

- Multi-Station Sequence: Detailed layout of sequential operations from initial piercing to final part cutoff.

- Precision Pilot Alignment: Features specialized pilot pins designed to maintain strip accuracy within microns across all stations.

- Integrated Strip Lifter System: Includes schematics for spring-loaded lifters to ensure smooth material advancement without snagging.

- Balanced Tonnage Design: Engineered to distribute press force evenly across the die set to prevent premature wear and deflection.

- Modular Insert Architecture: Showcases how to use interchangeable inserts for high-wear areas to simplify maintenance and repair.