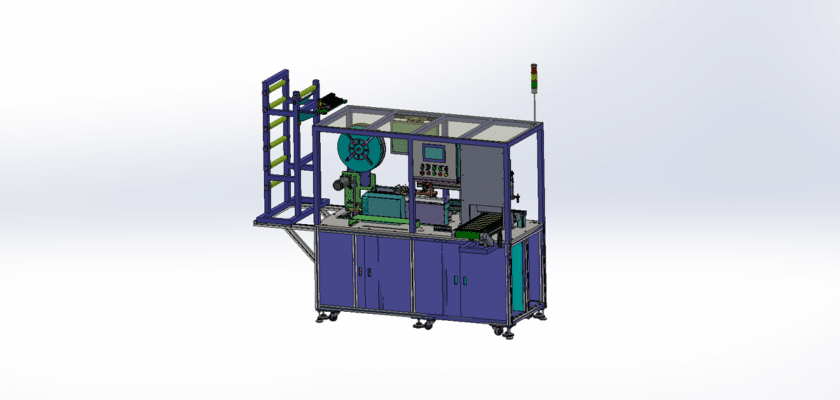

Un dessin de machine d'inspection de coupe de fil plat est une illustration technique qui détaille les composants et la disposition d'une machine conçue pour inspecter la qualité de coupe et la précision des fils plats.

Caractéristiques principales :

- Station de coupe:Schémas de la zone où les fils plats sont coupés, y compris les lames de coupe ou les mécanismes qui assurent la précision et la cohérence des longueurs de fil.

- Capteurs d'inspection:Représentation de capteurs ou de caméras utilisés pour vérifier la qualité de la coupe, en vérifiant les défauts tels que les bords effilochés, les longueurs incorrectes ou les désalignements.

- Système de convoyeur: Détails du tapis roulant ou du système de manutention automatisé qui transporte les fils coupés à travers la zone d'inspection pour un traitement efficace.

- Unité de contrôle: Informations sur l'unité de traitement qui gère les opérations de coupe, interprète les données des capteurs et contrôle la fonctionnalité globale de la machine.

- Interface utilisateur:Illustrations du panneau de commande ou de l'écran tactile où les opérateurs peuvent surveiller le processus d'inspection, ajuster les paramètres et visualiser les résultats en temps réel.

- Systèmes de sortie de données: Diagrammes montrant comment les résultats d'inspection sont rapportés, par exemple via des affichages numériques, des alarmes pour les défauts ou des journaux de données pour l'analyse de la qualité.

- Alimentation électrique: Détails concernant les besoins en énergie, y compris les connexions électriques et tous les systèmes de secours pour assurer un fonctionnement continu.

Ce dessin sert de référence complète pour les ingénieurs et techniciens impliqués dans la conception, l'assemblage et la maintenance des machines d'inspection de coupe de fils plats, garantissant des normes élevées de contrôle de qualité et d'efficacité opérationnelle dans les processus de fabrication de fils.