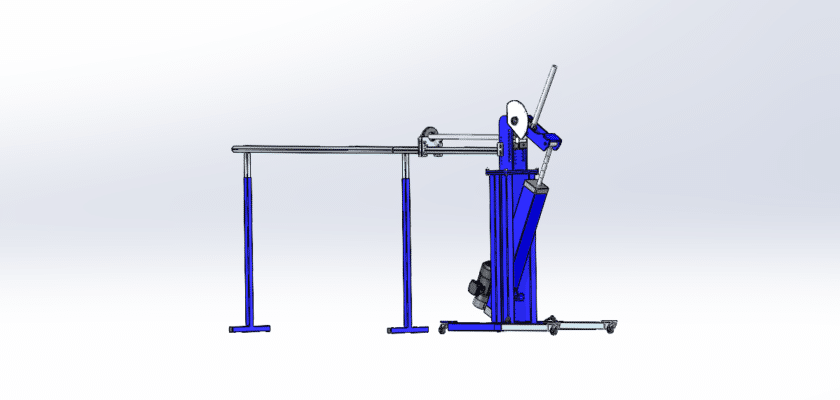

Ce dessin détaillé de la cintreuse de tubes CNC entièrement automatique illustre un système sophistiqué conçu pour le cintrage précis de tubes et tuyaux dans divers matériaux, notamment l'acier, l'aluminium et le cuivre. Idéale pour les fabricants de secteurs tels que l'automobile, l'aéronautique et la construction, cette machine optimise la productivité tout en garantissant des cintrages de haute qualité et des dimensions précises.

Principales caractéristiques du dessin :

- Contrôle CNC entièrement automatisé:La machine utilise la technologie avancée CNC (Computer Numerical Control) pour automatiser le processus de pliage, augmentant considérablement l'efficacité et réduisant le travail manuel.

- Mécanisme de pliage de haute précision:Équipé d'outils de pliage de précision et de paramètres réglables, le système garantit des angles précis et des résultats cohérents sur une large gamme de tailles et d'épaisseurs de tuyaux.

- Interface de contrôle conviviale:Le panneau de commande intuitif permet aux opérateurs de programmer facilement les spécifications de pliage et de surveiller les performances en temps réel, facilitant ainsi les ajustements rapides pour différents projets.

- Compatibilité des matériaux polyvalents:Conçu pour gérer différents types de tuyaux et de tubes, ce qui le rend adaptable à diverses applications dans plusieurs industries.

- Fonctionnalités de contrôle qualité intégrées:Des systèmes de mesure et d'inspection intégrés vérifient que chaque tuyau plié répond à des normes de qualité strictes, minimisant les défauts et améliorant la fiabilité globale.

- Construction robuste et durable:Construite à partir de matériaux de haute qualité, la machine est conçue pour la longévité et la fiabilité, garantissant des performances optimales dans des environnements de production exigeants.

Ce dessin sert de référence essentielle pour les ingénieurs et les fabricants cherchant à mettre en œuvre des solutions de cintrage de tuyaux efficaces et efficientes dans leurs processus de fabrication.