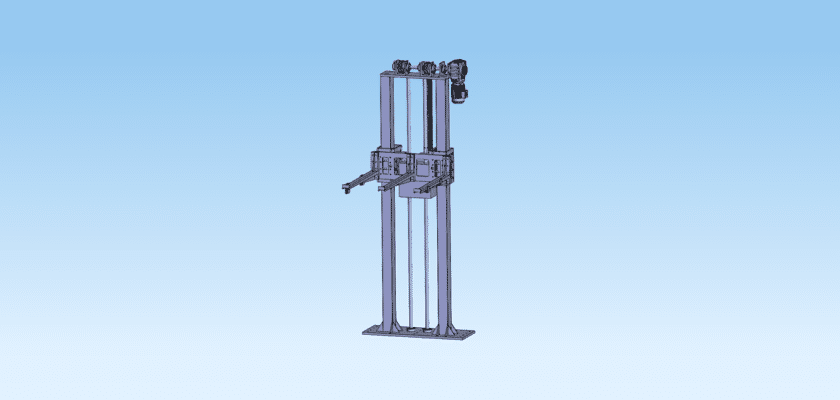

Optimize your vertical material flow with our exclusive, free drawing package pour le Hydraulic Reciprocating Lifter! Often referred to as a VRC (Vertical Reciprocating Conveyor) or industrial freight elevator, this equipment is essential for transferring materials, pallets, or totes between different floor levels in warehouses, distribution centers, and manufacturing plants. Utilizing a hydraulic drive system ensures heavy load capacity, smooth operation, and superior durability for continuous, repetitive up-and-down cycles.

Ce comprehensive technical drawing set provides the detailed blueprints for constructing a robust, floor-to-floor reciprocating lifter. The plans detail the structural tower framework, the robust lifting carriage (platform), the sizing and mounting of the hydraulic cylinders and sheaves, and the crucial safety interlocking gates and controls. Logistics engineers, automation designers, facility managers, and mechanical students will find these accurate, industry-standard drawings invaluable for building, maintaining, or integrating highly efficient vertical transport systems. Stop relying on manual or inefficient methods for floor-level transfers. By downloading this critical design asset today, you gain the foundational technical knowledge for building a compliant and powerful hydraulic lifter. Secure your free lifter drawing now and streamline your vertical material handling!

Caractéristiques principales :

- Structural Tower Design: Detailed blueprints of the welded steel mast or guide rails and the overall framework required to support the lifting carriage and load safely.

- Système d'entraînement hydraulique : Schematics illustrating the cylinder mounting, cable/chain synchronization system (if used), and the HPU connections optimized for repetitive, controlled vertical strokes.

- Lifting Carriage and Platform: Drawings detailing the platform structure, load capacity specifications, and methods for interfacing with floor-level conveyors or loading docks.

- Safety Interlocks and Gates: Blueprints specifying the design and location of perimeter guarding, safety enclosures, and electrically interlocked access gates at each level to prevent falls.

- Controlled Descent Mechanism: Details on the hydraulic flow controls and relief valves essential for governing the speed of lowering and preventing uncontrolled drops under heavy load.