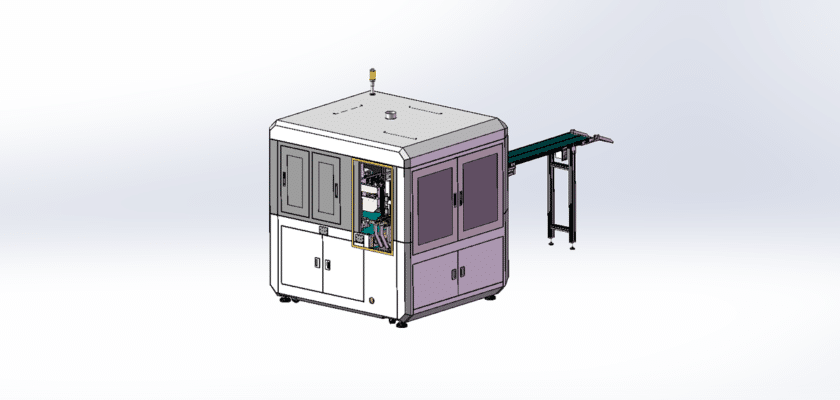

An Inkjet Laminating Machine Drawing is a technical illustration that outlines the design and functionality of a machine specifically engineered for the application of inkjet printing and lamination processes. This type of machine is essential in industries such as packaging, graphics, and document finishing, where high-quality printing and protection of printed materials are crucial.

Caractéristiques principales :

- Overall Layout: A comprehensive view of the machine’s structure, showcasing the arrangement of components and their interactions during the printing and laminating processes.

- Material Feeding System: Diagrams illustrating the mechanisms that supply substrates (e.g., paper, film) to the machine, including unwinding rollers and tension controls to ensure smooth handling and alignment.

- Inkjet Printing Unit: Representation of the inkjet printing mechanism, detailing the print heads, ink supply systems, and any integrated technology for high-resolution printing.

- Lamination Unit: Information about the lamination system, which may include heated rollers or flatbed laminators that apply a protective film over printed materials to enhance durability and appearance.

- Drying Mechanism: Details about the systems used to dry the ink after printing, which may involve heated air, UV lights, or other drying technologies to ensure quick and effective drying.

- Cutting and Trimming Unit: Information on the mechanisms that cut or trim the laminated material to the desired size, ensuring accuracy and minimizing waste.

- Control Panel: Illustrations of the central control unit that manages the operation of the machine, allowing operators to monitor processes, adjust settings, and access real-time performance data.

- User Interface: Information about the touchscreen or control panel that provides operators with intuitive access to machine settings, including print quality, lamination thickness, and cutting parameters.

- Quality Control Systems: Diagrams showing integrated sensors or cameras that monitor the printing and lamination processes for consistency and quality assurance.

- Data Output Systems: Information on how production data, including output counts and quality metrics, are logged and communicated, featuring digital displays for immediate feedback.

- Mechanical Framework: Details about the structural components that support the machine, ensuring stability and durability during operation.

- Caractéristiques de sécurité: Information regarding safety mechanisms, such as emergency stops, safety guards, and sensors to ensure safe operation throughout the printing and laminating processes.

- Power Supply: Information about the electrical requirements and backup systems to ensure reliable operation.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of inkjet laminating machines, ensuring high standards of efficiency, accuracy, and operational effectiveness in the printing and lamination processes.