Achieve sub-micron inspection accuracy with our professional technical documentation for the Inner Diameter Core Deviation Measuring Table. In high-precision manufacturing—particularly for hydraulic cylinders, engine liners, and aerospace bushings—measuring the deviation of an internal core relative to the outer datum is critical for performance and longevity. This drawing package details a specialized inspection station designed to hold cylindrical workpieces with zero-play rigidity while high-sensitivity dial indicators or LVDT probes map the internal geometry.

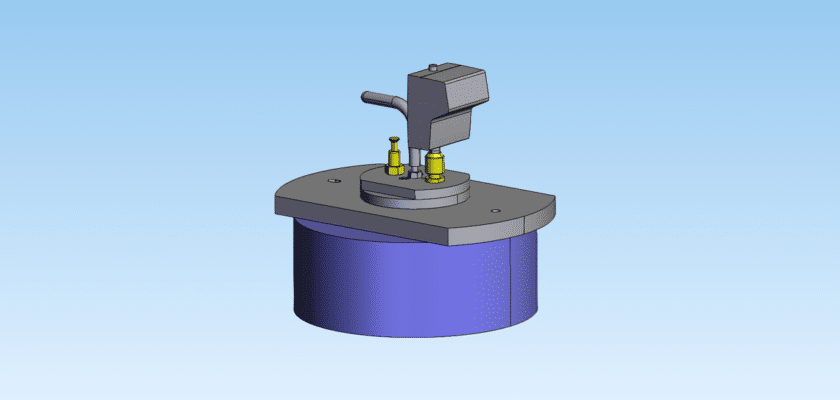

The provided dessin package offers an exhaustive look at the precision-ground surface plate, the adjustable V-block supports, and the rotating spindle assembly. By analyzing the thermal stability requirements and the vibration-dampening mounting points in these blueprints, engineers can build a measurement environment that eliminates external “noise” and provides repeatable data. We provide these high-fidelity CAD resources for free to help quality control teams identify core shift, eccentricity, and ovality issues before parts reach final assembly.

Our files are formatted for seamless integration into 3D engineering environments, allowing you to simulate the probe path and contact points for various workpiece lengths and diameters. Utilizing this professional blueprint ensures that your metrology lab can handle complex inspection tasks with the highest degree of confidence. Download this essential resource today to standardize your concentricity checks and reduce the risk of catastrophic component failure.

Caractéristiques principales :

- High-Precision Spindle Interface: Features a low-friction, high-accuracy rotating center to allow for 360-degree deviation mapping.

- Modular Probe Mounting: Detailed layouts for multi-axis indicator holders, accommodating various probe types and reaches.

- Granite or Ground Steel Base: Optimized for maximum flatness and thermal mass to ensure measurement stability across shifts.

- Adjustable Workpiece Length Support: Includes a sliding tailstock or steady-rest design to inspect long-core components without deflection.

- Ergonomic Fine-Adjustment Knobs: Specifically engineered for “zeroing” instruments with high tactile sensitivity.