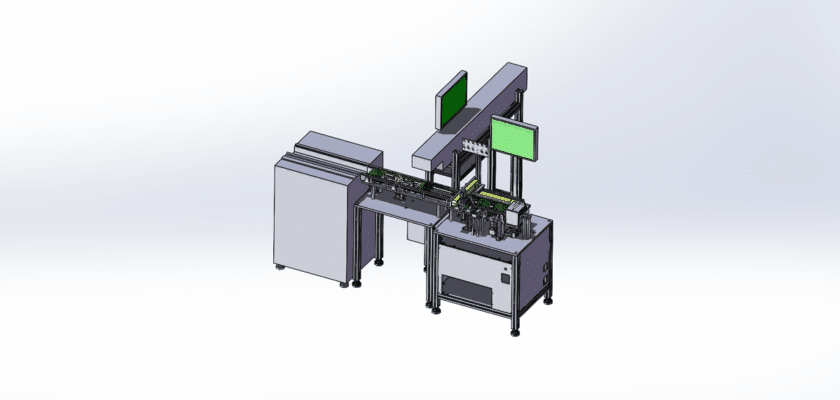

An LED Component Packaging and Detection Machine Drawing is a technical illustration that outlines the design and layout of a specialized machine engineered for the automated detection and packaging of LED components. This equipment is crucial for ensuring the quality, reliability, and efficiency of LED products used in various applications.

Caractéristiques principales :

- Système d'alimentation: Diagrams showing the mechanism that supplies LED components to the detection and packaging line, ensuring a continuous and organized flow of products for processing.

- Detection Unit: Representation of the sensors and testing mechanisms used to verify the functionality and quality of each LED component. This section may include details about electrical testing, brightness measurement, and visual inspections.

- Mécanisme de tri: Information about the system that sorts LED components based on detection results, separating defective units from those that meet quality standards for packaging.

- Unité d'emballage: Details about the machinery responsible for forming, filling, and sealing packaging materials, specifying the types of packaging used (e.g., trays, bags, or boxes) and how LED components are arranged for optimal protection and presentation.

- Mécanisme d'étanchéité:Informations sur la manière dont les emballages sont scellés après le remplissage, ce qui peut inclure le scellage adhésif, le thermoscellage ou d'autres méthodes pour garantir des fermetures sécurisées.

- Panneau de contrôle:Illustrations de l'unité de contrôle centrale qui gère l'ensemble du fonctionnement de la machine, permettant aux opérateurs de surveiller les processus, d'ajuster les paramètres et de visualiser les données de performance en temps réel.

- Interface utilisateur: Détails sur l'écran tactile ou le panneau de commande qui offre aux opérateurs un accès intuitif aux paramètres de la machine, aux capacités de surveillance et aux fonctionnalités de rapport de production.

- Systèmes de sortie de données: Diagrams showing how detection results and production data are logged and communicated, including digital displays for immediate feedback and connections for reporting to external systems.

- Système de convoyeur: Information about the conveyors that transport LED components through various stages of detection, sorting, and packaging, ensuring smooth and efficient movement.

- Cadre mécanique: Détails sur les composants structurels qui soutiennent la machine, assurant la stabilité et la précision pendant le fonctionnement.

- Alimentation électrique:Informations concernant les exigences électriques et les systèmes de secours pour assurer un fonctionnement fiable.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of LED component packaging and detection machines, ensuring high standards of efficiency, quality control, and operational effectiveness in the production process.