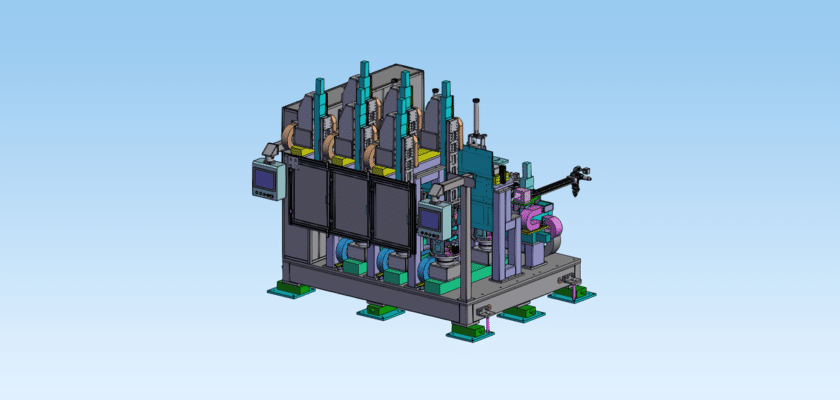

Scale up your energy storage production with our exclusive, free drawing package pour le Large-Diameter Lithium Battery Fully Automatic Welding Machine! As the industry shifts toward high-capacity cells like the 4680 and 4695 formats, precision welding of the collector plates and tabs is absolutely critical. This fully automated system is designed to handle the increased thermal mass and structural requirements of large-diameter cylinders, ensuring ultra-stable electrical connectivity and hermetic seals. It is indispensable for EV battery pack manufacturing and grid-scale storage solutions where high-speed throughput and zero-defect quality are mandatory.

Ce comprehensive technical drawing set provides the detailed blueprints for constructing a high-tech battery assembly module. The plans detail the precision indexing turntable, the high-speed fiber laser welding head integration, the intelligent CCD vision alignment system, and the non-destructive weld monitoring sensors. Battery technology engineers, automation system integrators, and clean-room equipment designers will find these accurate, industry-standard drawings invaluable for building or scaling advanced battery production lines. Stop being limited by small-cell technology. By downloading this critical design asset today, you gain the foundational technical knowledge for building a compliant and high-efficiency large-diameter battery welder. Secure your free machine drawing now and power the future of electrification!

Caractéristiques principales :

- High-Precision CCD Alignment: Detailed blueprints specifying the camera mounting and lighting geometry for sub-millimeter positioning of the laser beam on the battery terminal.

- Fiber Laser Head Integration: Schematics illustrating the multi-axis motion control and gas shielding nozzles optimized for high-conductivity materials like copper and aluminum.

- Multi-Station Indexing System: Drawings detailing the cam-driven or servo-motorized turntable designed to transport large cells through loading, cleaning, and welding phases.

- Intelligent Pressure Control: Blueprints showing the pneumatic or voice-coil actuators that ensure perfect contact between the tab and terminal before the weld pulse initiates.

- Weld Quality Monitoring: Details on the integration points for infrared thermal sensors and ultraviolet photodetectors used for real-time, 100% inspection of every weld joint.