Enhance your machine safety and positioning accuracy with our comprehensive technical documentation for the Locking-Free Stopping Device. Unlike traditional friction brakes or pin-locks that can become wedged or difficult to release under load, a “locking-free” design utilizes specialized geometry—often based on cam-action or wedge-release principles—to ensure that the stop is as easy to disengage as it is to apply. This is critical for automated systems, adjustable workbenches, and emergency stop-blocks where reliability and speed are the top priorities.

The provided dessin package offers a deep dive into the internal tolerances and the surface-hardening requirements necessary to prevent material “cold welding” under high pressure. By analyzing the spring-return paths and the contact-angle geometry in these blueprints, engineers can build a device that provides rock-solid holding power while maintaining a smooth, effortless release. We offer these high-fidelity CAD resources for free to help designers create safer, more responsive industrial equipment.

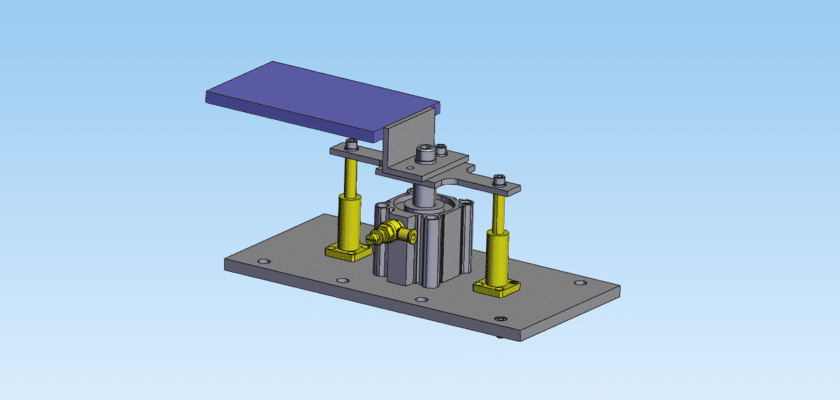

Our files are ready for immediate use in professional 3D environments, allowing for detailed kinematic analysis of the engagement and disengagement phases. This ensures that even under maximum rated load, the device will not “lock-up,” protecting your actuators and preventing operator frustration. Download this essential resource today to add a sophisticated, fail-safe stopping solution to your mechanical library.

Caractéristiques principales :

- Anti-Jamming Geometry: Engineered with specific release angles to ensure the device never becomes “set” or stuck under heavy axial loads.

- Instant Engagement: Designed for rapid response times, providing immediate stopping power for linear or rotary motion.

- Low-Friction Release Path: Features polished contact surfaces and specialized coatings to minimize the force required to reset the device.

- Heavy-Duty Load Rating: Designed for construction with hardened alloys (e.g., 4140 or O1 tool steel) to resist deformation at the stop point.

- Compact Modular Housing: A space-saving design that can be easily integrated into existing slide rails, cylinders, or manual adjustment columns.