Maximize your material processing capacity with our professional technical documentation for the Long Stroke Cutting Mechanism. Unlike standard short-stroke trimmers, this assembly is engineered for operations requiring deep penetration or the shearing of thick-walled profiles and large-format sheets. By utilizing an optimized stroke-to-force ratio, this mechanism ensures a clean, perpendicular cut throughout the entire travel distance, making it ideal for the textile, rubber, and heavy-gauge metal industries.

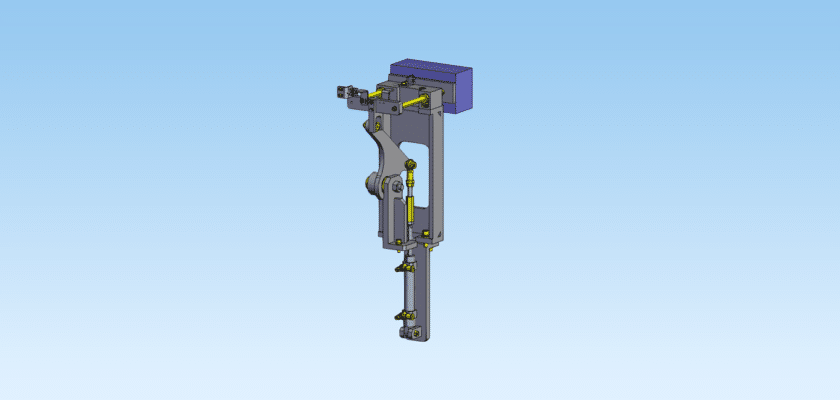

The provided dessin package offers an exhaustive look at the reinforced guide rails and the high-stability ram assembly required to prevent “blade deflection” during extended travel. By analyzing the cylinder mounting points and the counter-balance system detailed in these blueprints, engineers can design a cutting station that operates with minimal vibration and maximum safety. We provide these high-fidelity CAD resources for free to help manufacturing teams build robust machinery capable of handling the most demanding longitudinal or vertical cutting tasks.

Our files are compatible with all major 3D engineering platforms, allowing you to perform detailed stress analysis (FEA) on the blade carrier and support frame. This ensures that the mechanism maintains its structural integrity even when cutting high-tensile materials at the full extent of its stroke. Download this professional blueprint today to bring industrial-grade shearing power and precision to your production floor.

Caractéristiques principales :

- Extended Reach Geometry: Engineered for high-clearance operations, allowing for the processing of bulky or thick-layered materials.

- Anti-Deflection Guide System: Features heavy-duty linear bearings or gibs to ensure the blade remains perfectly aligned over the long travel distance.

- Optimized Force Distribution: Designed to maintain consistent cutting pressure from the start of the stroke to the bottom dead center (BDC).

- Hardened Tool Steel Blade Layout: Includes specifications for oversized, shock-resistant blades (e.g., S7 or A2 steel) to handle high-impact loads.

- Integrated Safety Guarding: Pre-designed mounting points for light curtains and physical shielding to protect operators during the long cycle.