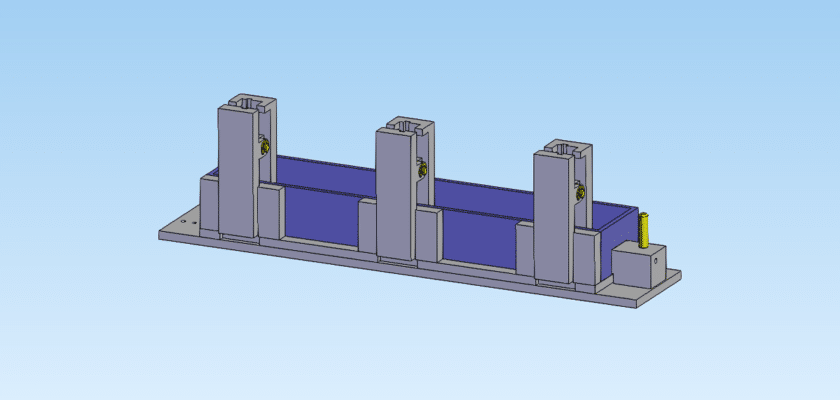

Eliminate vibration and deflection by choosing to download our professional Long Workpiece Clamping Fixture drawing. Machining elongated components—such as aircraft wing spars, drive shafts, or industrial rails—presents unique challenges, primarily regarding harmonic chatter and material sagging. This technical drawing provides a complete mechanical blueprint for a specialized multi-point clamping system designed to provide continuous, rigid support across the entire length of a workpiece. It is an indispensable resource for production engineers looking to maintain tight tolerances on parts where traditional vises fall short.

By utilizing this comprehensive CAD resource, your design team can analyze the specialized “bridge” or “cradle” architecture required to counteract the cutting forces applied at the center of a long span. The drawing covers the synchronization of multiple clamping units and the integration of adjustable jacks or steady rests that prevent “bowing” during heavy milling or turning. Whether you are working with thin-walled tubing or heavy structural beams, these schematics offer the verified data needed for thermal expansion compensation and repeatable part registration. Accessing this verified design ensures your shop can achieve superior surface finishes and prevent costly part distortion.

Caractéristiques principales :

- Distributed Clamping Pressure: Detailed schematics for multiple independent or synchronized clamping modules that ensure equal force application along the longitudinal axis.

- Integrated Anti-Vibration Supports: Structural insights into the placement of damping pads and adjustable jacks to eliminate harmonic chatter in the center of long spans.

- Thermal Expansion Compensation: A clever mechanical design that allows the workpiece to expand or contract during high-heat operations without losing registration.

- Modular Rail-Base System: A versatile mounting architecture that allows the fixture to be extended or shortened based on the specific length of the workpiece.

- High-Precision Datum Alignment: Specifications for the ground reference surfaces that ensure the long workpiece remains perfectly parallel to the machine’s travel axes.