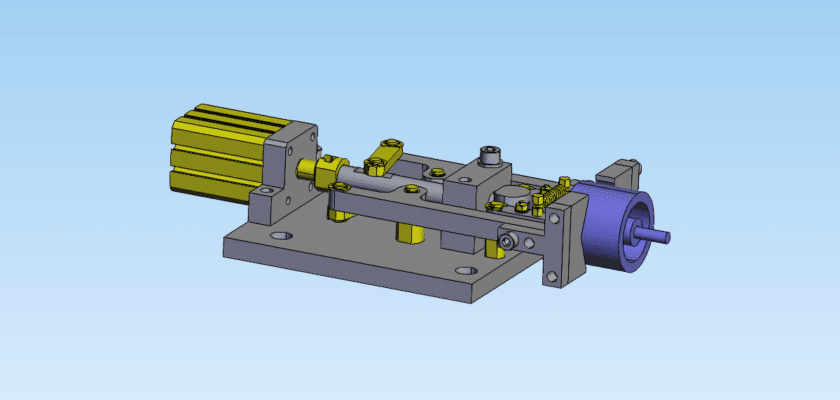

Double your machine productivity without increasing robot speed with our professional Manipulator Holding Two Workpieces Simultaneously drawing. In high-speed CNC tending or injection molding, “dead time” occurs when a robot arrives empty-handed to pick a finished part. This technical CAD resource provides a blueprint for a Dual-Grip End-Effector that allows a robot to carry a “raw” part and a “finished” part at the same time. By downloading this file from MechStream, you gain access to a design that enables a “swap” operation at the workstation, cutting transit cycles in half.

The design featured in this package focuses on the Back-to-Back or Side-by-Side Actuation architecture. The drawing includes detailed layouts for independent pneumatic or electric control of each jaw set, ensuring that one workpiece can be released while the other remains securely held. By utilizing this blueprint, you can design EOAT (End-of-Arm Tooling) that handles different geometries simultaneously—for example, a gripper that holds a housing in one set of jaws and a bearing in the other for immediate press-fit assembly.

Our technical documentation prioritizes weight optimization and center-of-gravity (CoG) management. To prevent overloading the robot’s wrist, the assembly is designed using high-strength 7075 aluminum and features integrated air manifolds to reduce hosing clutter. Whether you are building a palletizing cell or a precision electronics assembly line, this drawing provides the exact bolt patterns for major robot brands (FANUC, ABB, UR), payload calculations, and sensor mounting paths required for a professional-grade multi-handling installation.

Caractéristiques principales :

- Independent Jaw Control: Features dual-channel pneumatic routing to allow for asynchronous pick and place operations.

- Compact Tandem Geometry: Engineered to minimize the “sweep radius” of the robot arm, allowing for operation in tight machine enclosures.

- Payload-Balanced Design: Optimized structural layout to keep the center of mass as close to the robot’s J6 axis as possible, reducing motor strain.

- Fail-Safe Grip Retention: Includes blueprints for integrated check valves or spring-closed jaws that maintain a grip on both parts during a loss of power or air.

- Universal Mounting Flange: Designed to meet ISO 9409-1 standards for easy integration with standard industrial robot arms.