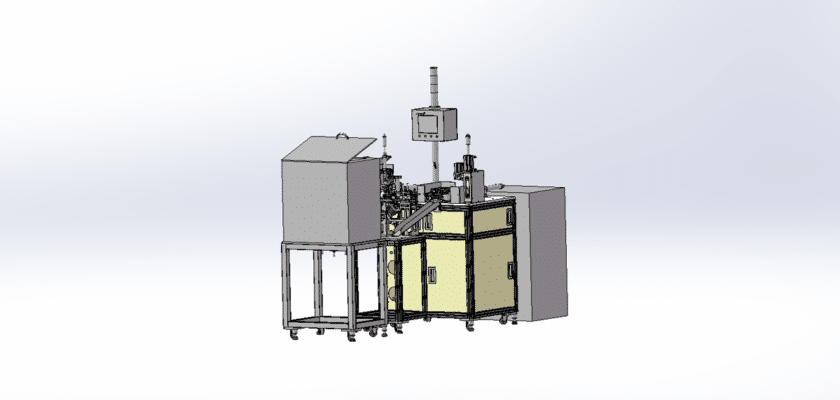

Ce schéma détaillé de l'équipement d'assemblage de bandes magnétiques pour coques de moteurs illustre un système spécialisé conçu pour l'assemblage automatisé de bandes magnétiques sur les coques de moteurs. Idéal pour les fabricants des secteurs des moteurs électriques et de l'automobile, cet équipement améliore l'efficacité de la production tout en garantissant un assemblage et des performances de haute qualité.

Principales caractéristiques du dessin :

- Processus d'assemblage automatisé:La machine utilise une technologie d'automatisation avancée pour rationaliser l'application de bandes magnétiques sur les coques de moteur, augmentant considérablement le débit et réduisant les coûts de main-d'œuvre manuelle.

- Alignement de haute précision:Équipé de guides et de capteurs de précision, le système assure un placement précis des bandes magnétiques, garantissant une adhérence et des performances optimales.

- Interface de contrôle conviviale:Un panneau de commande intuitif permet aux opérateurs de définir et de surveiller facilement les paramètres d'assemblage, facilitant des réglages rapides pour différentes conceptions de coque de moteur et spécifications de bande magnétique.

- Systèmes intégrés de contrôle de la qualité:Des mécanismes d'inspection intégrés surveillent en permanence le processus d'assemblage, garantissant que chaque coque de moteur avec bandes magnétiques répond à des normes de qualité strictes et minimise les défauts.

- Compatibilité d'application polyvalente:Conçu pour s'adapter à une variété de tailles et de formes de coques de moteur, ce qui le rend adaptable à diverses applications dans plusieurs secteurs.

- Construction robuste et durable:Construit à partir de matériaux de haute qualité, l'équipement est conçu pour la longévité et la fiabilité, garantissant des performances optimales dans les environnements de production à haut volume.

- Manutention efficace des matériaux:La machine peut inclure des systèmes d'alimentation et d'alignement automatisés pour rationaliser les processus de chargement et de déchargement, améliorant ainsi l'efficacité opérationnelle globale.

Ce dessin sert de référence essentielle pour les ingénieurs et les fabricants cherchant à mettre en œuvre des solutions d'assemblage efficaces et efficientes pour les coques de moteur avec bandes magnétiques dans leurs lignes de production.