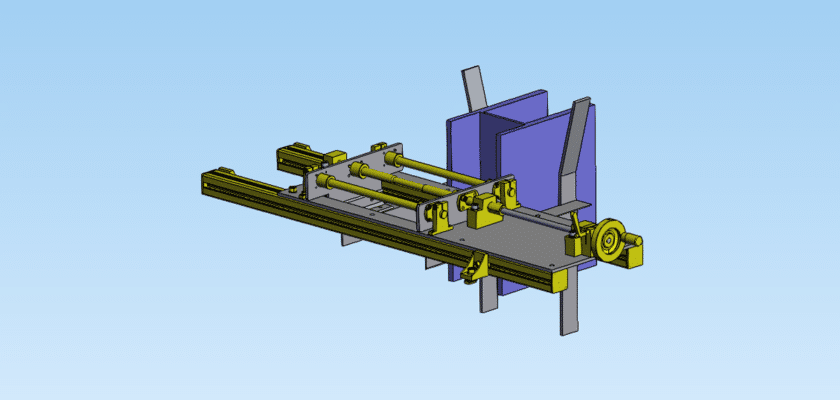

Maximize the flexibility of your packaging line with our professional Movable Guide Rail for Packing Machine drawing. In high-speed bottling, bagging, or boxing operations, the ability to rapidly resize conveyor lanes is the difference between a profitable shift and a bottleneck. This technical CAD resource provides a comprehensive blueprint for a laterally adjustable rail system designed to stabilize products of varying widths as they move through filling, sealing, and labeling stations. By downloading this file, you gain access to a design that prevents product tipping and “shingling” (overlap) by maintaining a perfect, centered path.

The design featured in this package focuses on a Synchronized Dual-Rail Adjustment. The drawing includes detailed layouts for a central hand-wheel or pneumatic actuator linked to a left-hand/right-hand lead screw, ensuring that both rails move toward or away from the centerline simultaneously. By utilizing this blueprint from MechStream, you can eliminate the tedious task of manually aligning each side of the conveyor, ensuring that the container always enters the packing head perfectly indexed. This is a vital asset for designers of food and beverage lines, pharmaceutical cartoners, and e-commerce fulfillment sorters.

Our technical documentation emphasizes low-friction contact and hygiene. The assembly is designed with high-molecular-weight (UHMW) polyethylene liners and stainless steel hardware to meet FDA/USDA standards for washdown environments. Whether you are building a new secondary packaging machine or retrofitting an existing conveyor, this drawing provides the exact geometric tolerances, slider block specifications, and vibration-resistant locking features required for a professional-grade, high-uptime installation.

Caractéristiques principales :

- One-Touch Width Calibration: Features a synchronized drive system that adjusts both guide rails from a single point of control.

- Low-Friction UHMW Liners: Detailed specifications for wear-resistant, food-grade inserts that protect product labeling and reduce conveyor drag.

- Rigid Support Brackets: Engineered to withstand the lateral pressure of heavy containers without bowing or losing alignment.

- Digital Position Feedback: Includes integrated mounts for digital counters or scales, allowing for precise, repeatable changeovers for specific SKU sizes.

- Quick-Release Clamping: Designed with “tool-less” handles that allow for rapid height or width micro-adjustments during live production.