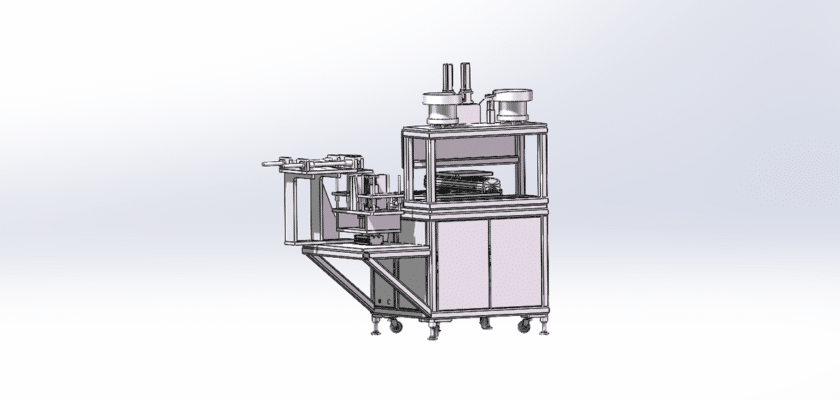

Ce dessin détaillé de la machine de pose de clous illustre un système spécialisé conçu pour la pose efficace et précise de clous dans diverses applications, notamment le travail du bois, la construction et la fabrication de meubles. Cette machine optimise les processus de production tout en garantissant une fixation de haute qualité.

Principales caractéristiques du dessin :

- Fonctionnement automatisé:La machine utilise une technologie d'automatisation avancée pour rationaliser le processus de placement des clous, augmentant considérablement la vitesse et réduisant les besoins en travail manuel.

- Mécanisme d'alignement de précision:Équipé de guides de précision, le système assure un positionnement précis des clous, minimisant ainsi les risques de mauvais positionnement et de dommages matériels.

- Panneau de configuration convivial:Une interface intuitive permet aux opérateurs de définir et d'ajuster facilement les paramètres, facilitant des changements rapides pour différentes tailles de clous et matériaux.

- Construction robuste:Construite avec des matériaux de haute qualité, la machine est conçue pour la durabilité et la fiabilité, garantissant des performances constantes dans les environnements de production à haut volume.

- Compatibilité des matériaux polyvalents:Capable de manipuler divers matériaux, notamment le bois, le plastique et les composites, la machine s'adapte à une large gamme d'applications de fixation.

- Fonctionnalités de sécurité améliorées:La conception intègre des mécanismes de sécurité tels que des boutons d'arrêt d'urgence et des barrières de protection, garantissant un fonctionnement sûr pour tous les utilisateurs.

- Manutention efficace des matériaux:Un système d'alimentation automatisé peut être inclus pour rationaliser le chargement et le positionnement des clous, améliorant ainsi l'efficacité globale du flux de travail.

Ce dessin sert de référence essentielle pour les ingénieurs et les fabricants cherchant à mettre en œuvre des solutions efficaces de placement de clous dans leurs lignes de production.