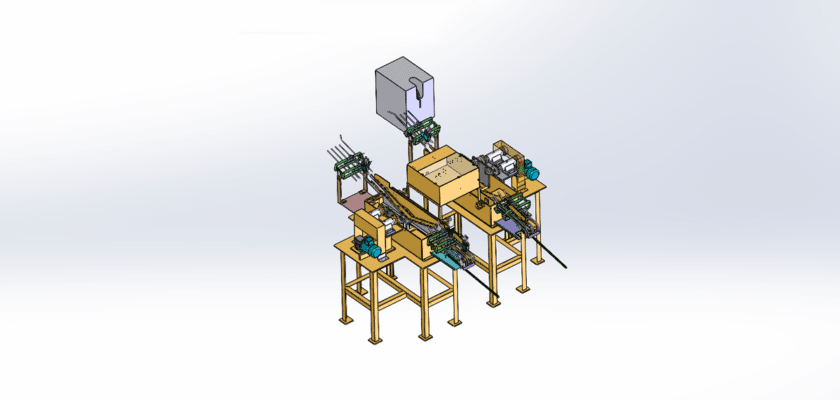

Le schéma d'un système d'alimentation automatique non standard présente un schéma détaillé d'un système d'alimentation personnalisé conçu pour automatiser la distribution de matériaux ou de produits en milieu industriel et manufacturier. Il met en évidence les composants et caractéristiques essentiels garantissant un fonctionnement efficace, une adaptabilité et une fiabilité optimales.

Caractéristiques principales :

- Configuration du chargeurLe dessin illustre l'agencement général de l'alimentateur automatique, mettant en valeur sa conception unique, adaptée à des types de matériaux et des exigences opérationnelles spécifiques. Il comprend la disposition des trémies, des goulottes et des sections de convoyage.

- Mécanisme de manutention des matériauxDes informations détaillées sur le mécanisme d'alimentation sont fournies, qui peut inclure des plateaux vibrants, des convoyeurs à bande ou des vis sans fin. Cette section explique comment les matériaux sont acheminés de la source d'approvisionnement à la zone de traitement ou d'assemblage, garantissant un flux fluide et continu.

- Systèmes de contrôleUne présentation des mécanismes de contrôle est incluse, détaillant le fonctionnement de l'alimentateur automatique. Cela peut impliquer des automates programmables (API), des capteurs pour la détection des matériaux et des interfaces conviviales pour les réglages. Les dispositifs de sécurité tels que les boutons d'arrêt d'urgence et les capteurs de surcharge sont clairement indiqués.

- Système d'alimentationLe schéma met en évidence les systèmes d'alimentation utilisés pour faire fonctionner l'alimentateur, notamment les moteurs électriques et les mécanismes d'entraînement. Les spécifications relatives à la puissance du moteur, au contrôle de la vitesse et au rendement énergétique sont incluses pour garantir des performances fiables.

- Structure de soutienLe châssis robuste et le système de support sont illustrés, soulignant la stabilité et la durabilité nécessaires pour supporter le poids des matériaux pendant le fonctionnement. La conception comprend des points d'ancrage et des évaluations structurelles pour garantir une utilisation en toute sécurité.

- Caractéristiques de sécurité:Les composants de sécurité essentiels, tels que les protections, les verrous de sécurité et les mécanismes d'arrêt d'urgence, sont illustrés pour promouvoir un fonctionnement sûr et la conformité aux normes de sécurité de l'industrie.

- Accessibilité de la maintenance:La conception comprend des fonctionnalités qui permettent un accès facile aux composants critiques pour la maintenance et les inspections de routine, facilitant ainsi un entretien efficace et minimisant les temps d'arrêt.

- Options de personnalisation:Les zones désignées pour la personnalisation sont mises en évidence, permettant des ajustements en fonction du type de matériau, de la taille et des besoins opérationnels spécifiques, garantissant ainsi la flexibilité dans diverses applications.

Ce dessin constitue une ressource essentielle pour les ingénieurs, les responsables de production et le personnel de maintenance, fournissant des informations complètes sur la conception, la mise en œuvre et le fonctionnement des alimentateurs automatiques non standard dans diverses applications industrielles.