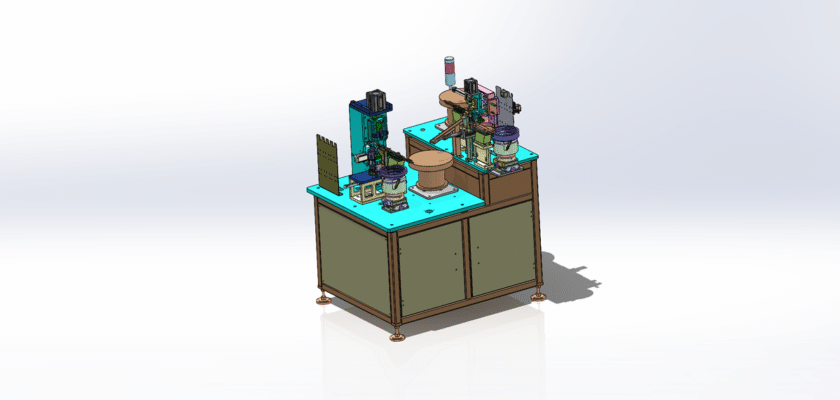

Le Machine d'assemblage de goupilles de fourche pour accessoires de montre de précision non standard Il s'agit d'un équipement spécialisé conçu pour l'assemblage minutieux des accessoires horlogers, notamment des axes de fourche, avec une précision extrême. Dans l'industrie horlogère, où la précision est primordiale, cette machine offre des performances exceptionnelles en garantissant un alignement précis et une efficacité optimale de chaque axe de fourche.

L’une des caractéristiques clés de ce machine non standard est-ce que c'est personnalisationConçue pour répondre aux besoins spécifiques de l'assemblage d'accessoires horlogers, elle offre une grande flexibilité aux fabricants qui recherchent des solutions sur mesure. Sa polyvalence lui permet de traiter différentes tailles de broches, la rendant ainsi adaptée à différents types de montres.

L'équipement précision est un aspect remarquable, garantissant que chaque axe de fourche est inséré et aligné parfaitement, minimisant ainsi le risque de défauts ou de dysfonctionnements dans le produit final. technologie de pointe intégrée dans sa conception, la machine maintient des opérations à grande vitesse tout en conservant des tolérances serrées, contribuant à un processus de production plus efficace.

De plus, le fiabilité de cette machine d'assemblage garantit des temps d'arrêt minimes lors des longues séries de production, ce qui en fait un outil précieux pour les fabricants de montres cherchant à améliorer leur productivité sans compromettre la qualité. interface conviviale permet une utilisation facile, même pour les techniciens moins expérimentés, garantissant une intégration transparente dans les flux de production existants.

En conclusion, le Machine d'assemblage de goupilles de fourche pour accessoires de montre de précision non standard est un choix idéal pour les entreprises horlogères qui privilégient l'assemblage de haute qualité, la personnalisation et la stabilité opérationnelle à long terme, tout en améliorant l'efficacité globale de la production.