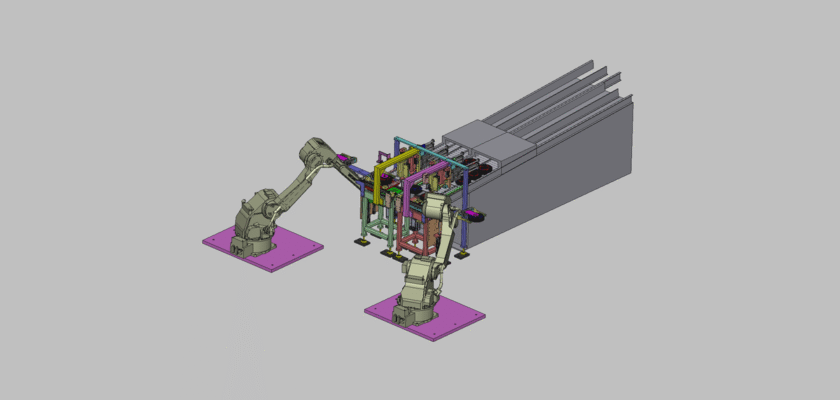

Prêt à dynamiser votre production ? Téléchargez gratuitement notre Dessins de lignes d'assemblage automatisées de robots Dès aujourd'hui, prenez une longueur d'avance pour construire l'avenir de votre usine. Ces schémas, soigneusement élaborés, constituent le plan essentiel d'un système de production automatisé à haute efficacité. Une chaîne de montage robotisée remplace les tâches humaines répétitives par des robots précis et performants, ce qui permet un débit plus élevé, une qualité supérieure et une sécurité renforcéeNos dessins détaillent la conception des systèmes de convoyage, des cellules de travail robotisées et des points d'intégration critiques qui assurent un fonctionnement fluide. Idéale pour les ingénieurs mécaniciens, les intégrateurs de systèmes et les étudiants, cette ressource est une passerelle vers la compréhension et la mise en œuvre de l'automatisation avancée. De la construction automobile à l'électronique grand public, une chaîne de montage robotisée révolutionne tout secteur nécessitant un assemblage de précision en grande série. N'attendez plus : améliorez vos capacités de production et réduisez vos coûts en obtenant ces dessins performants dès aujourd'hui.

Caractéristiques principales :

- Haute précision et répétabilité : Les conceptions mettent l’accent sur l’intégration de bras robotisés avec des capteurs avancés, garantissant que chaque tâche est exécutée avec une précision et une cohérence parfaites à chaque fois.

- Fonctionnalités de sécurité intégrées : Les dessins comprennent des spécifications pour les enceintes de sécurité, les rideaux lumineux et les systèmes d'arrêt d'urgence pour créer un environnement de travail sécurisé pour les humains et les machines.

- Conception modulaire et évolutive : Les plans sont basés sur un concept modulaire, vous permettant de faire évoluer facilement la chaîne de montage en ajoutant ou en reconfigurant des stations robotisées à mesure que vos besoins de production évoluent.

- Intégration de systèmes de vision et de capteurs : Les plans détaillent comment intégrer des systèmes de vision et d’autres capteurs pour le contrôle qualité, l’inspection des pièces et les ajustements en temps réel pour maintenir des performances optimales.

- Flux de travail optimisé : La chaîne de montage est conçue pour minimiser les goulots d'étranglement et maximiser le débit, avec des bandes transporteuses synchronisées et des mouvements robotiques coordonnés pour créer un flux de production continu.