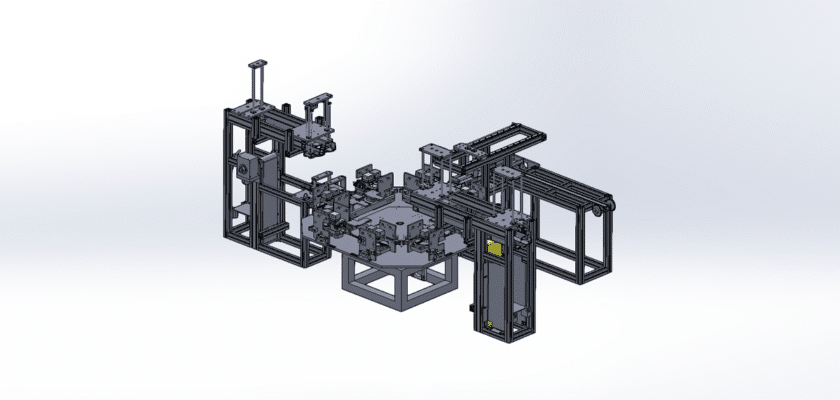

UN machine d'emballage de corde à sauter Il s'agit d'un système automatisé conçu pour emballer efficacement et uniformément les cordes à sauter destinées à la vente au détail et à la distribution. Cet équipement spécialisé est essentiel pour les fabricants d'articles de fitness, car il automatise un processus répétitif et laborieux. Grâce à cette machine, les entreprises peuvent considérablement accélérer leur production, réduire les erreurs d'emballage et garantir un aspect professionnel et uniforme à leurs produits. La machine plie ou enroule les cordes à sauter, les insère dans un sac ou une boîte, puis ferme l'emballage. Le schéma détaillé, téléchargeable gratuitement, fournit un aperçu détaillé d'un système d'emballage professionnel. C'est une ressource indispensable pour les ingénieurs mécaniciens, les designers industriels et les chefs d'entreprise souhaitant automatiser leurs processus d'emballage. L'étude de ces plans vous permettra de comprendre la mécanique, les capteurs et les systèmes de contrôle qui permettent des opérations d'emballage rapides et fiables.

Caractéristiques principales :

- Automatisation à grande vitesse : La conception est conçue pour un fonctionnement rapide et continu, capable d'emballer des centaines de cordes à sauter par heure pour répondre aux exigences de la production à grande échelle.

- Système de manutention polyvalent : Le dessin détaille un système de manutention flexible qui peut être ajusté pour s'adapter à différentes longueurs de corde et gérer différents types de poignées, garantissant ainsi l'adaptabilité à une large gamme de produits.

- Comptage et alimentation précis : Les plans montrent un système intégré avec des capteurs et des convoyeurs qui comptent et alimentent avec précision les cordes à sauter individuelles jusqu'à la station d'emballage, évitant ainsi un emballage excessif ou insuffisant.

- Mécanisme d'étanchéité intégré : La machine comprend une unité de thermoscellage ou de collage intégrée, détaillée sur le dessin, pour fermer en toute sécurité les sacs ou les boîtes, garantissant l'intégrité du produit de l'usine au client.

- Conception robuste et fiable : La machine est construite avec des composants durables pour résister à une utilisation continue dans un environnement industriel, garantissant une fiabilité à long terme et une maintenance minimale.