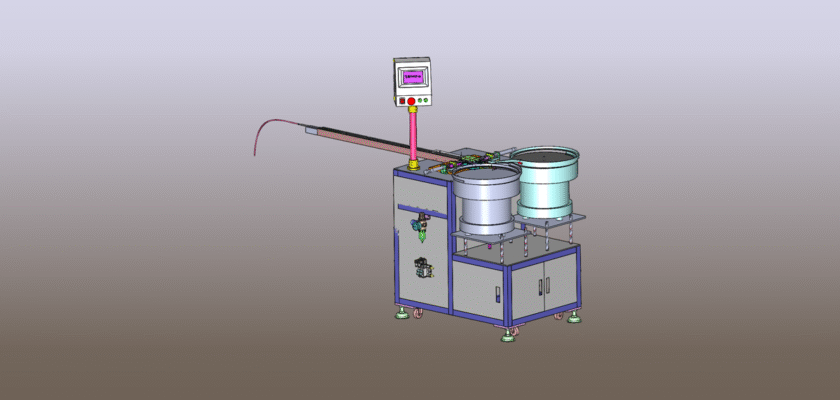

Streamline your production line with our exclusive drawing of an Automated Rope Skipping Threading Machine. This free, downloadable CAD file provides the complete blueprint for a machine specifically designed to automate the tedious process of threading ropes through handles. This is a must-have resource for sporting goods manufacturers and engineers looking to dramatically increase efficiency, ensure product consistency, and reduce labor costs in the assembly of jump ropes.

By downloading this detailed drawing, you gain access to a professionally engineered solution that can be built and integrated directly into your workflow. The design covers every aspect of the machine, from the initial feeding of the rope and handles to the final threading action and ejection. This blueprint is your key to overcoming production bottlenecks and scaling up your manufacturing capacity. Move away from slow, manual assembly and embrace a faster, more reliable automated process with this essential design file.

Caractéristiques principales :

- Automatic Rope Feeding & Cutting: The design includes a mechanism with rollers and a blade that automatically pulls rope from a spool, measures it to a precise length, and cuts it cleanly.

- Handle Hopper & Orientation System: Features a magazine or hopper that holds a bulk quantity of handles and automatically orients them correctly for the threading process.

- Pneumatic Threading Mechanism: At its core is a powerful and fast pneumatic actuator with a specialized pusher that accurately guides and threads the rope through both handle holes in a single motion.

- Sensor-Based Control: Incorporates designated locations for optical or proximity sensors to detect the presence of the rope and handles, ensuring a smooth and error-free automated cycle.

- Finished Part Ejection: Once threaded, a simple mechanism automatically ejects the completed jump rope into a collection bin, allowing for continuous, unattended operation.