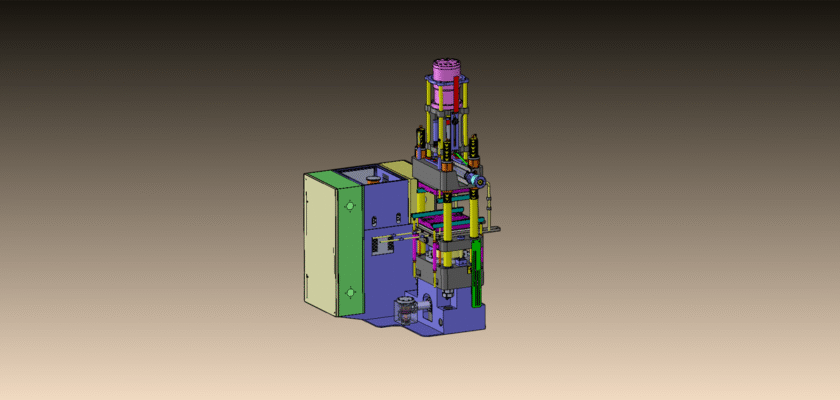

UN rubber molding machine is a piece of industrial equipment used to transform raw rubber into final, usable products. These machines are essential in manufacturing everything from seals and gaskets to automotive parts and consumer goods. They operate by applying intense heat and pressure to raw rubber, forcing it to take the shape of a pre-designed mold. The most common types are compression molding, transfer molding, et moulage par injection machines, each suited for different production needs. This comprehensive drawing provides a detailed blueprint of a professional-grade rubber molding machine. It is an invaluable resource for mechanical engineers, product designers, and students in industrial design, offering a deep look into the machine’s intricate mechanics, hydraulic systems, and thermal controls. By downloading this drawing, you can gain a foundational understanding of the principles of material processing and how to design equipment that ensures high precision and consistency in manufacturing.

Caractéristiques principales :

- High-Precision Molding: The drawing provides accurate, detailed representations of the machine’s components, including the clamping unit, hydraulic cylinders, and heating platens, which are crucial for achieving tight tolerances and consistent product quality.

- Application polyvalente : The design can be adapted for different types of rubber molding processes, making it a flexible tool for a wide range of applications, from producing simple O-rings to complex multi-component parts.

- Integrated Thermal Control: The blueprints show a system for precise temperature regulation, which is vital for the vulcanization process to ensure the rubber cures correctly and achieves its desired mechanical properties.

- Durable & Robust Design: The machine is engineered for continuous, heavy-duty industrial use, with a solid frame and high-quality components built to withstand the immense pressure and heat of the molding process.