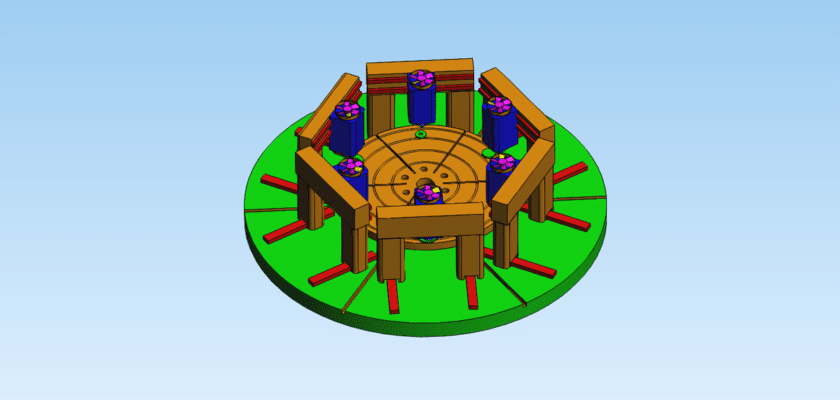

Maximize your manufacturing throughput with our comprehensive CAD drawing of a Six-Station Linkage Combination Punch Press. This advanced industrial resource showcases a sophisticated mechanical system where six distinct workstations are driven by a singular, coordinated linkage assembly. Unlike standalone presses, this combination unit allows for multiple operations—such as piercing, notched cutting, and forming—to occur simultaneously or in rapid succession, all powered by a centralized drive shaft.

By downloading this technical dessin, you can examine the complex kinematics required to maintain precise timing across all six stations. The layout provides detailed views of the toggle linkages, cam-followers, and synchronized sliders that ensure each station hits its target with repeatable accuracy. This resource is invaluable for engineers looking to design high-speed automated production cells or for those studying the mechanical advantage provided by multi-bar linkage systems. At MechStream, we offer these professional-grade blueprints to help you master the integration of complex mechanical motions into a single, compact machine footprint. Download this multi-station press layout today and elevate your machine design capabilities.

Caractéristiques principales :

- Synchronized Multi-Station Drive: A centralized linkage system that ensures all six stations operate in perfect harmony, reducing motor overhead.

- High-Torque Toggle Links: Engineered to provide maximum force at the bottom of the stroke for heavy-duty punching and forming.

- Modular Station Blocks: Features independent die-mounting areas for each station, allowing for quick retooling of specific operations.

- Vibration-Dampening Frame: A heavy-duty cast or welded structure designed to absorb the multi-directional forces generated by six simultaneous strokes.

- Precision Timing Adjustment: Includes specifications for adjustable eccentric cams to fine-tune the stroke sequence for different material requirements.