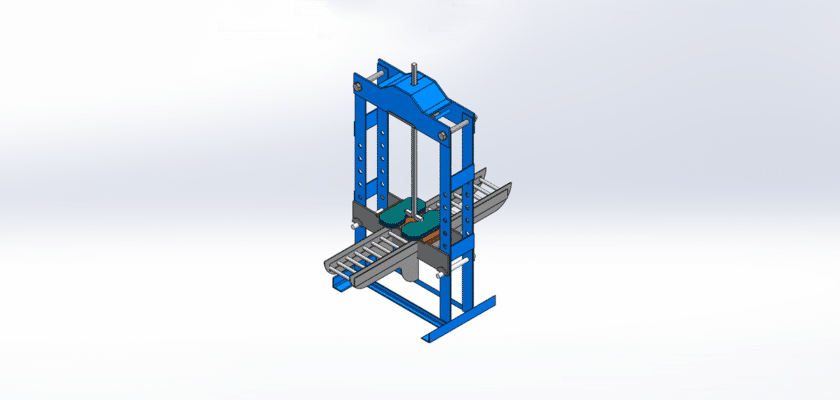

La découpeuse de semelles avec convoyeur est un outil hautement performant conçu pour la découpe précise des semelles de chaussures dans l'industrie de la chaussure. Cette machine est équipée d'un système de convoyeur qui alimente automatiquement la zone de découpe, permettant un fonctionnement à grande vitesse et une productivité accrue.

Conçue pour traiter différents types de matériaux tels que le caoutchouc, le cuir et les composés synthétiques, cette machine garantit des coupes nettes et précises à chaque fois. Le système de convoyage optimise le flux de travail en rationalisant le processus de production et en réduisant les manipulations manuelles, améliorant ainsi l'efficacité et la sécurité dans les environnements à fort volume.

Les réglages réglables de la machine permettent aux opérateurs d'adapter la profondeur et la vitesse de coupe à différents types de semelles et épaisseurs de matériaux. Grâce à sa construction robuste, la machine à découper les semelles avec convoyeur est conçue pour une performance durable, supportant une utilisation continue sans compromettre la précision ni la fiabilité.

L'interface conviviale et les commandes intuitives permettent une configuration et un réglage rapides de la machine, même pour différents lots de production. De plus, sa conception compacte lui permet de s'adapter à diverses configurations de lignes de production, économisant ainsi de l'espace tout en maintenant des performances élevées.

Outre l'amélioration de la précision et de la vitesse de découpe, cette machine contribue à réduire le gaspillage de matière et à améliorer la qualité globale du produit. C'est une solution économique pour les fabricants de chaussures qui cherchent à optimiser leurs lignes de production, à augmenter leur rendement et à garantir une qualité de produit constante.